Vertical Ultrasonic Machining Tool 1000W Ultrasonic Milling Components

Description| Frequency: | 20khz | Power: | 1000W |

|---|---|---|---|

| Amplitude: | 15~50um | Gap Overcut: | 0.02-0.1 |

| High Light: | ultrasonic assisted drilling,ultrasonic milling components | ||

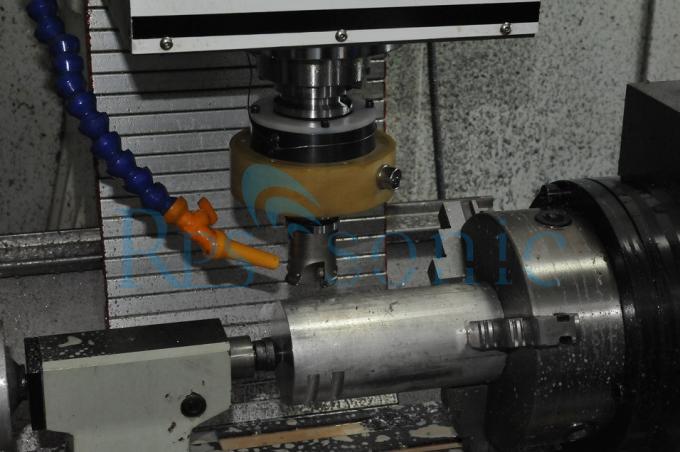

Vertical ultrasonic machining tool ultrasonically vibrating mill ccomponents

Introduction:

| Item | Parameter |

| Abrasive | Boron carbide, aluminium oxide and silicon carbide |

| Grit size(d0) | 100 – 800 |

| Frequency of vibration (f) | 19 – 25 kHz |

| Amplitude of vibration (a) | 15 - 50 µm |

| Tool material | Soft steel titanium alloy |

| Wear ratio | Tungsten 1.5:1 and glass 100:1 |

| Gap overcut | 0.02-0.1 mm |

An ultrasonically vibrating mill consists of two major components, an electroacoustic transducer and a sonotrode, attached to an electronic control unit with a cable. An electronic oscillator in the control unit produces an alternating current oscillating at a high frequency, usually between 18 and 40 kHz in the ultrasonic range. The transducer converts the oscillating current to a mechanical vibration.

Piezoelectric transducer: This consists of a piece of piezoelectric ceramic, such as barium titanate, with two metal electrodes plated on its surface. The alternating voltage from the control unit applied to the electrodes causes the piezoelectric element to bend back and forth slightly, causing it to vibrate.

The transducer vibrates the sonotrode at low amplitudes and high frequencies The sonotrode is usually made of low carbon steel.] A constant stream of abrasive slurry flows between the sonotrode and work piece. This flow of slurry allows debris to flow away from the work cutting area. The slurry usually consists of abrasive boron carbide, aluminum oxide or silicon carbide particles in a suspension of water (20 to 60% by volume). The sonotrode removes material from the work piece by abrasion where it contacts it, so the result of machining is to cut a perfect negative of the sonotrode's profile into the work piece. Ultrasonic vibration machining allows extremely complex and non-uniform shapes to be cut into the workpiece with extremely high precision.

Machining time depends on the workpiece's strength, hardness, porosity and fracture toughness; the slurry's material and particle size; and the amplitude of the sonotrode's vibration. The surface finish of materials after machining depends heavily on hardness and strength, with softer and weaker materials exhibiting smoother surface finishes. The inclusion of microcrack and microcavity features on the materials surface depend highly on the crystallographic orientation of the work piece's grains and the materials fracture toughness

Ultrasonic Machining Advantages and Disadvantages

Get to know about the advantages and disadvantages of machining process in order to make the right decision:

Advantages

-

Machined all sorts of hard materials

-

Produces fine finished and structured results

-

Produces less heat

-

Various hole cut shapes due to vibratory motion of the tool

Disadvantages

-

Requires a higher degree of integrity and skills

-

No certified record of radiography

-

Unnecessary large grain sizes causes defects

-

Additional repairs might be required due to spurious signs and misunderstanding of the process