Products Details

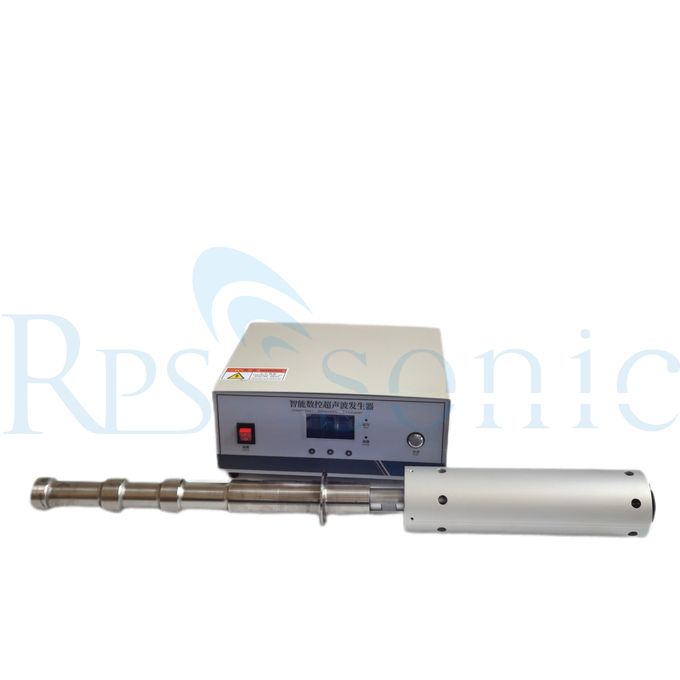

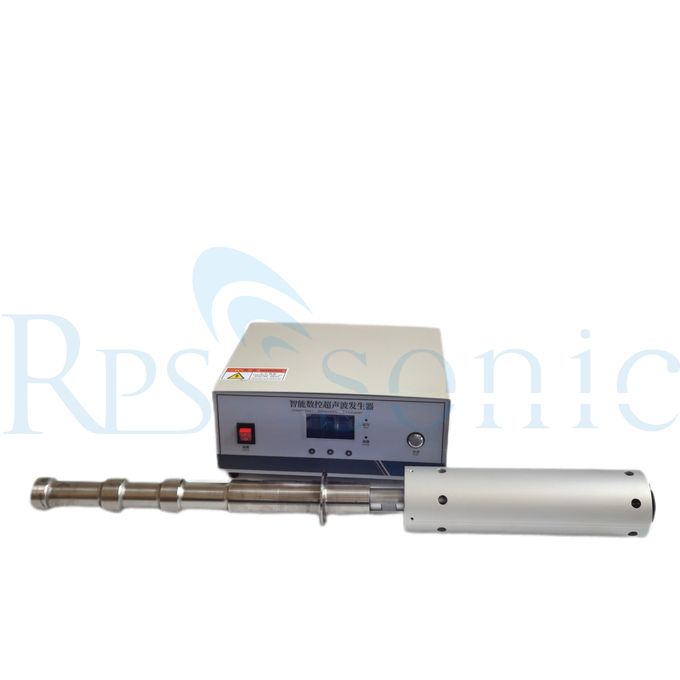

20Khz 1500w Ultrasonic homogenizer with titanium horn for Degassing and liquid defoaming

Parameter | Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

| Power | 1000 W | 2000 W | 3000 W | 3000 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

| Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description Cannabis oil and cannabis isolate have poor water solubility, which reduces their bioavailability and results in delayed treatment after oral or topical administration. However, when consumed in the form of nanoemulsions, they provide extremely high bioavailability and therapeutic effects, and are quickly and completely absorbed by the body. CBD American Shaman cooperated with ISM to develop a stable, water-soluble, all-natural nanoemulsion formula and production process, the nanoemulsion is made of CBD and hemp oil rich in terpenes. Under the action of ultrasonic energy, two or more immiscible solutions are mixed together, and one liquid is evenly divided into another liquid to form an emulsion. This treatment process is called oil-water emulsification. Ultrasonic equipment. Two liquids can form different types of emulsions, such as oil and water, oil-in-water emulsions, where oil is the dispersed phase and water is the dispersed nature; the two can form water-in-oil emulsions, and water is the dispersed phase, and oil is Continuous phase. At the same time, it is also possible to form multiple emulsion forms of "water-in-oil-in-water emulsion and oil-in-water-in-oil emulsion." Phacoemulsification is caused by cavitation. Ultrasound passing through the liquid causes it to continuously compress and expand. High-intensity ultrasound provides the energy needed to disperse the liquid phase, The cavitation process is affected by the frequency and intensity of ultrasonic waves. The appearance of cavitation in the body depends to a large extent on the presence of undissolved gas in the liquid suspension. The presence of gas seems to act as a catalyst. Under a certain pressure, the formation of the cavity depends to a certain extent on the development time and the ultrasonic frequency. The phacoemulsification process represents a competition between opposing processes. Therefore, it is necessary to select suitable working conditions and frequencies so that the destructive effects dominate. Features 1. The type of emulsion can be controlled; 2. Make the formed emulsion more stable; 3. High concentration; 4. Low power required to produce emulsion; 5. Low cost, ultrasonic emulsification-an important feature is that it can produce a very stable emulsion without or using less emulsifiers.

Ultrasonic Sonochemistry Homogenizer,

Ultrasonic Food Cutting,

China Doctor Hat Making Machine,

Waterproof ultrasonic welding converter,

Ultrasonic Vibration Cutting,

China Ultrasonic Cleaning Machine and 30L Ultrasonic Cleaner,

China Ultrasonic Bonding Design Roller,

analog generator,

Khz cutting blade,

Ultrasonic Tool Holder,