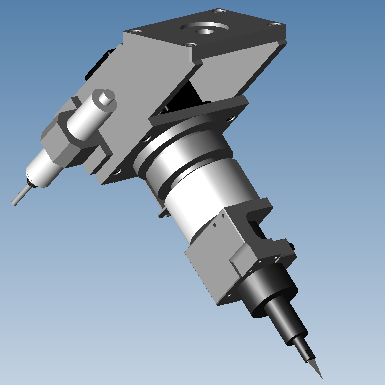

Robot Ultrasonic Cutting Device Routing Processing High Sewing Strength

Description| Frequency: | 20khz | Blade Material: | Rapid Steel |

|---|---|---|---|

| Cutting Thickness: | 4mm In Max | Applcation: | Plastics, Nonwoven Fabrics, Foams & Composites |

| Power: | 600W | Operate Type: | By Robot |

| High Light: | ultrasonic food cutter,ultrasonic slitting machine | ||

20khz robot Ultrasonic Cutting & Routing processing for plastics & composites

Introduction

Break the limitations of conventional cutting with a clean and agile alternative. ultrasonic solution delivers cleaner cuts and infinite flexibility for trimming, routing, deflashing and more. robotic tools add versatility and streamline changeovers for low-volume secondary operations.

Customize your cutsBuyers of custom-designed plastic, fiber and composite components are demanding shorter runs with a high level of customization. If your current tools aren't viable for handling low-volume orders, it's time to consider a solution that expands your capability to be agile and profitable without compromising quality.

Parameter

| Material | cutting thickness |

| ABS&PE | 4MM |

| 3MM | |

| PVC | 2MM |

| Non-woven | 2MM |

| Acrylic | 2MM |

| Neoprene | 5MM |

| corrugated plywood | 8MM |

| Fiberglass resin cardboard | 2.5MM |

| Linen (linoleum) urethane | 2MM |

| nylon | 3MM |

| PP | 3MM |

Advantages

1. Fast, economical, high sewing strength and strong tensile strength2. Independent cutting and sewing, with soft melting and trimming effect, no wire loss, no damage, no burrs.3. No need for auxiliary materials (such as staples, glue, paper clips, etc.). )4. No time-consuming warm-up and recovery required5, no pollution, no use of toxic adhesives and solvents, environmental protection and health6. There is no needle eye on the sewing edge, which can prevent the penetration of chemicals, pathogens and small harmful particles, which is safe and hygienic.

Combine the flexibility of robotics with specialized end-of-arm tooling options that optimize the speed, accuracy and quality of the job. Operate ultrasonic by robot is safe enough also can help you save cost on human.

Application:

Resin plateGlass fiber (GFRP) Formed decorative filmFoamBlow-molded partsInjection-molded partsCarbon fiber (CFRP)Aluminum foil compositesNon-woven fabricsControlled-depth kiss cutting