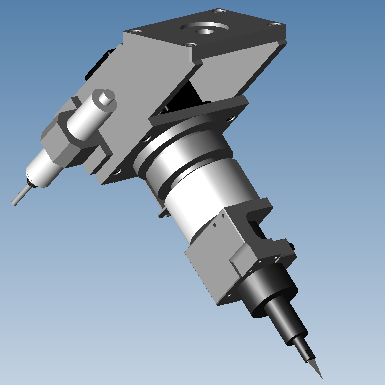

Robot Routing Processing ultrasonic cutting, trimming, deburring and chamfering

| Frequency: | 20khz | Blade Material: | Rapid Steel |

|---|---|---|---|

| Cutting Thickness: | 4mm In Max | Applcation: | Plastics, Nonwoven Fabrics, Foams & Composites |

| Power: | 600W | Operate Type: | By Robot |

| Application | ultrasonic cutting tool | ||

Robot Routing Processing ultrasonic cutting, trimming, deburring and chamfering

Parameter

Introduction

Ultrasonic Cutting & Routing An ultrasonic cutter is a type of device that uses wave energy to cut and process. The biggest feature is that it doesn't need traditional cutting edge. Traditional cutting uses sharp-edged cutting tools to press the material to be cut. The pressure is concentrated at the edge, and the pressure is very high, exceeding the shear strength of the material being cut. The molecular bonding of the material is pulled open and cut. Since the material is pulled out by strong pressure, the cutting tool's blade should be very sharp, and the material itself is subjected to relatively great pressure. The cutting effect of soft and elastic materials is not good, and it is more difficult for viscous materials.

| Material | cutting thickness |

| ABS&PE | 4MM |

| 3MM | |

| PVC | 2MM |

| Non-woven | 2MM |

| Acrylic | 2MM |

| Neoprene | 5MM |

| corrugated plywood | 8MM |

| Fiberglass resin cardboard | 2.5MM |

| Linen (linoleum) urethane | 2MM |

| nylon | 3MM |

| PP | 3MM |

Benefits of Ultrasonic Trimming

- No dust

- Reduced cutting force

- Unrivalled quality due to the absence of deformed cells and lint

- Significantly reduced cycle time (up to ×3 faster)

- Increased ultrasonic tool life span

- Possibility to realize complex geometries

Application:

Resin plateGlass fiber (GFRP) Formed decorative filmFoamBlow-molded partsInjection-molded partsCarbon fiber (CFRP)Aluminum foil compositesNon-woven fabricsControlled-depth kiss cutting