PLC Control Ultrasonic Welding High-performance ultrasonic generator power supply

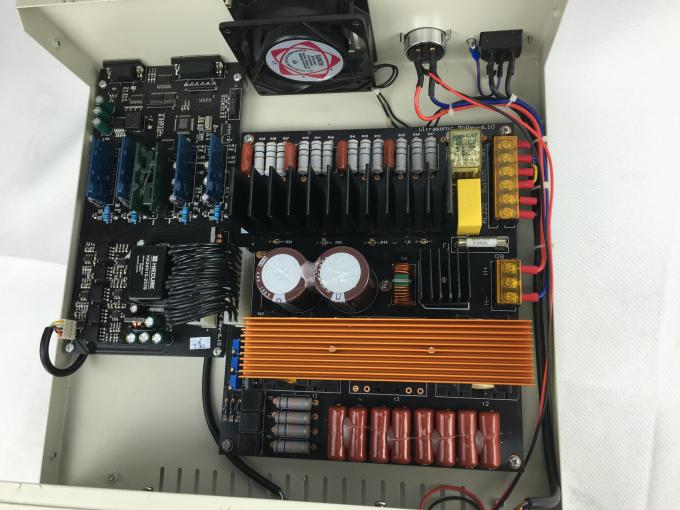

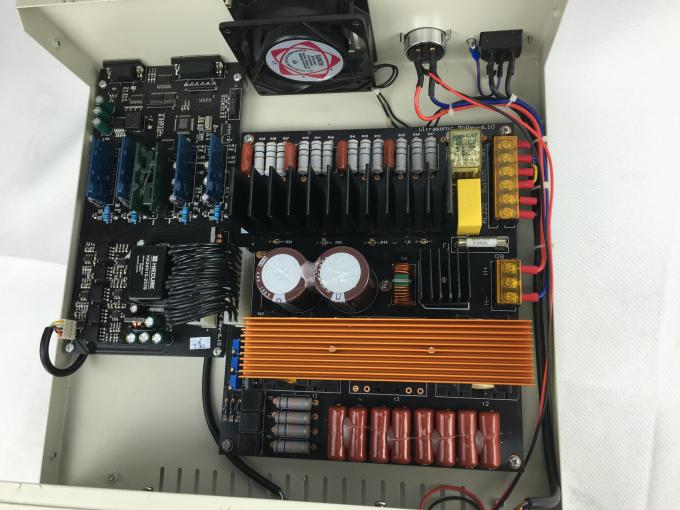

Ultrasonic generator, usually called ultrasonic generator, ultrasonic power supply. Its function is to convert our mains electricity (220V or 380V, 50 or 60Hz) into a high-frequency alternating current signal that matches the ultrasonic transducer. From the form of amplifying circuit, linear amplifying circuit and switching power supply circuit can be used, and high-power ultrasonic power supply generally adopts the circuit form of switching power supply considering the conversion efficiency.

Parameter:

| Item | Parameter |

| Power | 5000W In max |

| Frequency range | ±500hz |

| Operating temperature | ≤50℃ |

| Frequency | 20Khz~70khz |

| Counting capacity | 30000 item |

| Amplitude adjust | 10%~100% |

| Voltage | 110V/220V/380V |

| Circuit | Digital,separate excitation |

High-performance ultrasonic generator power supply is a new generation of ultrasonic generator developed by our company. Although the ultrasonic generator power supply is small and exquisite, it has the highest power-to-volume output ratio in the industry, and it is also equipped with leading closed-loop amplitude control. These features ensure that it can effectively provide excellent quality. Technical core: The most important thing in the ultrasonic working process is the two characteristic frequency tracking and constant amplitude. Frequency tracking: During the ultrasonic working process, the vibration system's temperature, stiffness, static load, processing area, tool wear and other factors change, which causes the natural frequency of the system to drift. This requires the ultrasonic generator to have the frequency automatic tracking function, and at the same time to ensure the processing quality And to protect the ultrasonic system, the generator is required to have the function of adjusting the output power according to the load. In order to solve the shortcomings in the frequency tracking of the piezoelectric transducer phase-locked loop, such as narrow tracking range, easy to mistrack and lose lock, inconvenient parameter adjustment, and serious temperature drift, our company directly uses digital frequency synthesis technology combined with digital lock The compound control technology of phase loop frequency tracking replaces all ultrasonic generators at home and abroad. Constant amplitude: In industrial production, even if the frequency tracking is good during the working process of the ultrasonic transducer, the change of the AC voltage supplied by the ultrasonic generator, the ultrasonic wave from no-load to the load, from tens of watts to several kilowatts, instantaneously changes within a few milliseconds, making the ultrasonic transducer The amplitude and power of the transducer will change accordingly. The transducer cannot achieve high efficiency, which makes the products processed by ultrasonic inconsistent, which is a common problem for ultrasonic equipment. In order to adapt to the industrial production process, the ultrasonic energy transmitted by the generator to the transducer is not subject to changes in load power and input voltage, and the generator automatically adjusts the amplitude within 1 millisecond, and has a constant amplitude function.