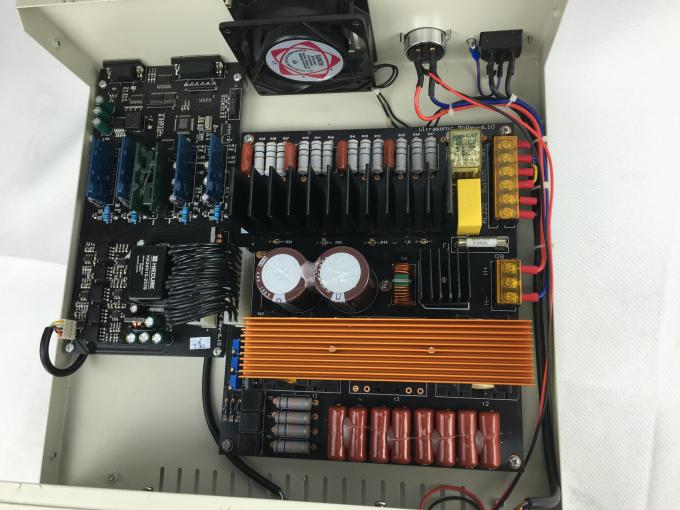

PLC Control Touch Screen Digital ultrasonic welding power supply

Description

| Frequency: | 15Khz~70khz | Power: | 5000W In Max |

|---|---|---|---|

| Excitement: | Separate Excitation | Generator: | Digital Generator |

| Operate: | PLC | Frequency Range: | +-500hz |

| Name: | Ultrasonic Welding Power Supply | ||

| High Light: | ultrasonic power generator,ultrasonic wave generator | ||

PLC Control Touch Screen Digital ultrasonic welding power supply

Ultrasonic welding generator, also known as ultrasonic welding power supply, is an important part of high-power ultrasonic system. The role of the ultrasonic generator is to convert the mains power into a high-frequency alternating current signal that matches the ultrasonic transducer and drive the ultrasonic transducer to work. From the aspect of conversion efficiency, high-power ultrasonic power supply generally adopts the circuit form of switching power supply. Ultrasonic power is divided into self-excited and self-excited power. Self-excited power is called ultrasonic analog power, and it is called ultrasonic generator.

Parameter:

Ultrasonic generator (ultrasonic power supply) is a power supply that converts 220v or 380v alternating current into an ultrasonic frequency electric oscillation signal. It is composed of oscillator, voltage amplifier, power amplifier and output transformer. In order to ensure the frequency stability of the ultrasonic generator and the impedance matching of the generator and the transducer, an acoustic tracking circuit and an automatic frequency tracking circuit are also installed in the ultrasonic generator. The development of ultrasonic generators is closely related to the development of electronic equipment. To a certain extent, the development of electronic automobiles dominates the development direction of ultrasonic generators. There are many types of ultrasonic generators. According to the different working principles used, they can be divided into analog circuits and digital circuits. According to the different power tubes used, they can be divided into three development stages: tube type, transistor type and analog. Integrated circuit type. 1 Tube type ultrasonic generator There are two types: self-excitation and other excitation, and self-excitation can be divided into frequency automatic tracking and acoustic tracking. As early as the 1950s, the electronic tube type has come out, its circuit type is simple, the dynamic range is large, but the volume is large, the power consumption is also large, and it has now been eliminated. 2 Transistor ultrasonic generator It can be divided into two stages: analog transistor type and switching transistor type. The development of transistor type has benefited from the improvement of the level of high-power devices and the increasing development of technical routes. Analog transistor type, mature circuit, low output power, long life, low cost, and it is widely used in small power occasions (less than 200w). Switch transistor type, combined with IC circuit type, the circuit type is simplified, the output power is large, the volume is small, the power is small, and it can be easily combined with the micro processor, becoming the mainstream development direction. 3 Analog integrated circuit type ultrasonic generator Compared with the transistor type, the analog integrated circuit type ultrasonic generator has two obvious advantages: First, when the generator output is low power, the working voltage of the transducer is greatly reduced. When the transistor generator outputs low power, the working voltage of the transducer reaches 148v, while when the analog integrated circuit generator outputs low power, the working voltage of the transducer is only 9v. Secondly, under the same working condition, the analog integrated circuit type generator has significantly reduced harmonic distortion than the transistor type. At present, ultrasonic generators with digital control have also come out, marking a big step towards intelligent development of ultrasonic generators. Here the ultrasonic generator is convenient to challenge the control scheme and realize a variety of new control strategies through the program software, which can realize automatic storage of operating data and automatic fault diagnosis.