One Piece Ultrasonic Cutting Device Non Woven Ultrasonic Slitting Machine

Description| Frequency: | 40khz | Blade Material: | Titumium |

|---|---|---|---|

| Cutting Thickness: | 1~7mm | Applcation: | Cutting By Robot |

| Power: | 500W | Operate Type: | Hand Held Or Robot |

| High Light: | ultrasonic cutting tool,ultrasonic slitting machine | ||

40Khz one-piece ultrasonic cutting machine for Non-woven sliting

Parameter

Introduction

Cutting process

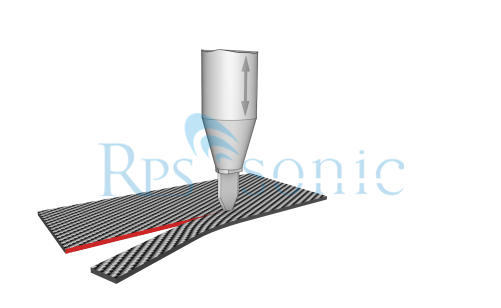

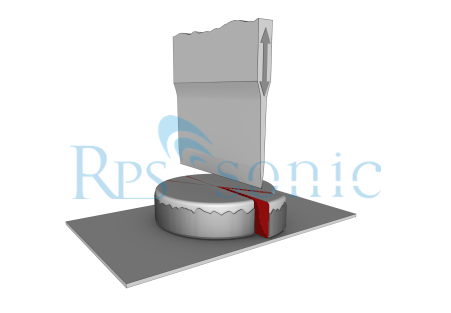

The main role of the ultrasonic cutting process is to separate the connected components. The high frequency vibration per second can reduce the pressure on the item to be cut. This results in a neat and clean cutting surface. In practical applications, it is divided into two processes, separated welding and cutting. Separation welding

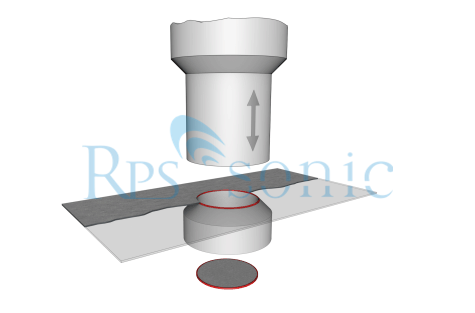

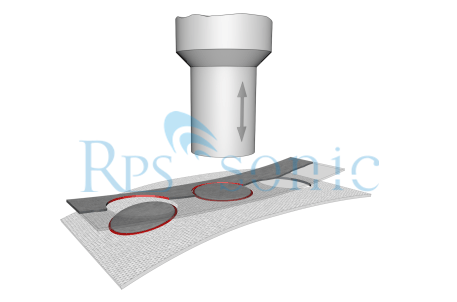

Ultrasonic energy can be used to cut thermoplastic multilayer textiles, non-woven materials or films into arbitrary shapes, and simultaneously weld along the cutting contour. The thermoplastic fiber content should be 20%. The cutting anvil with the corresponding cutting contour is cut by the vibration generated by the ultrasonic system. At the same time, the vibration attenuation generates heat in the cutting area, so that welding is performed along the cutting edge.

The cutting blade, which is vibrated by ultrasonic energy, quickly and accurately separates the items to be cut with minimal resistance without generating residue. Ultrasound has been used in finished product cutting for many years. When cutting baked foods, energy bars, cheeses, pizzas and other materials, the vibrating (cold) cutting welding horn can reduce the resistance during the cutting process and remove adhered product residues. The result: a flat, recuttable surface without distortion or thermal damage to the product.

Application area:

Cutting and sealing are performed and completed simultaneously. Both ends of the welding fiber can be cut simultaneously within one micron, which is a clear advantage in medical and filtration technology with high quality requirements. Continuous cutting and sealing.

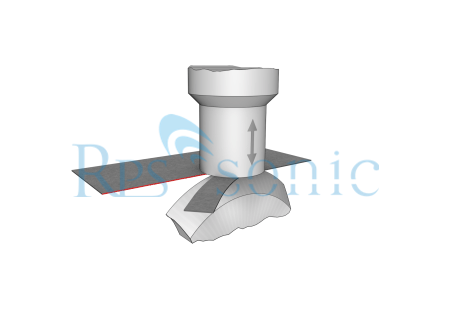

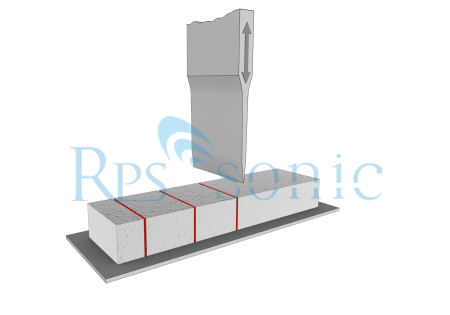

The advantage of ultrasonic cutting and sealing technology is that it can quickly and accurately seal and cut woven and non-woven fabrics in continuous operation

Flexible cutting of polymer and textile components must guarantee cutting edges at the fastest speed and accuracy. Ultrasonic treatment is the ideal process in the automotive industry.

Ultrasound cuts the product accurately and quickly with minimal resistance through high-speed vibration, and realizes no residue, no deformation and no thermal damage on the product surface.

Using ultrasonic frequency to drive the cutter vibration can easily cut into the material, and it is very accurate and saves material. Cutting solid materials

Ultrasonic vibration will be transmitted to the installed cutting blade by the welding horn to cut different materials cleanly, which will produce a cutting surface such as carbon fiber or rubber products.

Ultrasonic vibration will be transmitted to the installed cutting blade by the welding horn to cut different materials cleanly, which will produce a cutting surface such as carbon fiber or rubber products.