Manual Ultrasonic welding Machine for sound insulation board

Description

| Frequency: | 35khz | Power: | 800W |

|---|---|---|---|

| Horn: | 8mm | Horn Material: | Alumium Alloy Or Titanium Alloy |

| Generator: | Digital Generator | Weight: | 5kg In Totall |

| High Light: | handheld ultrasonic welder,ultrasonic welding equipment | ||

Manual Ultrasonic welding Machine for sound insulation board

Introduction:

Ultrasonic welding machine is a common equipment mainly used for thermoplastic connection. Compared with other plastic bonding technologies, ultrasonic plastic welding has excellent welding quality, high production efficiency, and is widely used. Ultrasonic welding has a wide range of applications, including electronics, electrical appliances, toys, many industries, automobiles and aerospace, civil engineering, medicine and packaging, and so on. If the sensor is fixed, the high power level will be fixed. Measuring output energy is a tedious overachievement. It is no longer to say that the larger the transducer, the more efficiency tubes used in the circuit, the greater the output energy. It needs the same extremely cumbersome amplitude measuring instrument to accurately measure its amplitude. Because most users know too much about ultrasound, some salespersons are misled and customers are misunderstood. The electrical energy consumed does not reflect the size of the excess output efficiency, just like low longitudinal energy and large current consumption. The oscillation frequency and amplitude range should be conceived based on factors such as workpiece material, welding wire area, whether there are electronic components in the workpiece, and whether it is airtight or not. Ultrasonic welding machine applies ultrasonic waves to plastic parts to melt them quickly, and then uses the pressure function of the ultrasonic welding machine to generate local heating (heating is the result of the combined effect of surface and molecular friction) and melts under pressure to form a weld , To achieve the purpose of welding. Many purchasing customers mistakenly believe that the higher the efficiency of the ultrasonic welding machine, the better.

Parameter| Item | Parameter |

| Frequency | 35Khz |

| Power | 800W |

| Vibration method | Self-extraction |

| Welding time | 0.01-9.99sec |

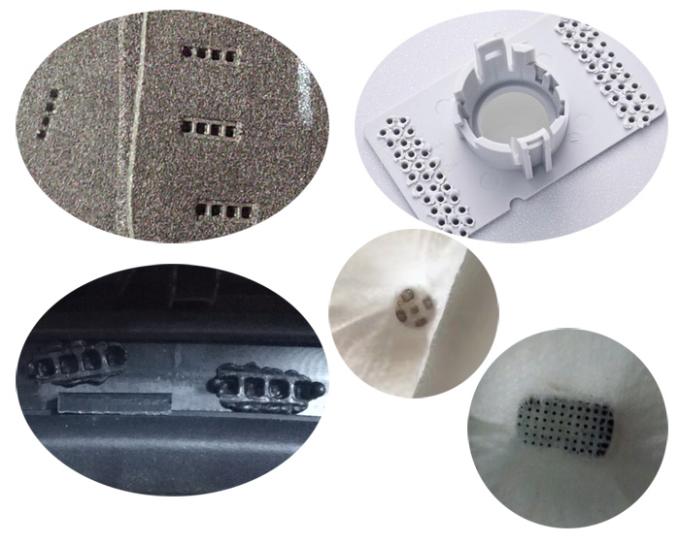

| Horn | Grid horn |

Application of ultrasonic spot welding machine:For decoration, ribbon spot welding, riveting, etc., portable spot welding machines are widely used in the clothing industry, trademark industry, automotive industry, plastic electronics, household goods industry, etc. Simple operation, high price and practical advantages.Apparel industry: sewing process of underwear and underwear, welding of webbing elastic band, etc .; can be used for spot drilling.Trademark industry: woven ribbons, printed ribbons, etc.Automotive industry: door sound insulation cotton, wiper seat, engine cover, water tank cover, etc.Plastic electronics: small plastic parts riveting, etc.Houseware industry: fiber cotton spot welding and so on.