20Khz 2000W Ultrasonic Tube Welding System for Plastic Cosmetic Tube Sealing

Suitable for plastic tube & aluminum laminated tubes

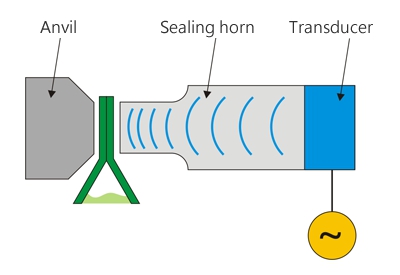

The plastic inside the tube is heated and melted by high frequency friction force introduced from ultrasonic horn. Clamps closed and cooled and formed the melted plastic to seal the tube. This methos is suitable for production of small to medium capacity.

Advantages:

-

Only contacted areas are heated. The physical and chemical characteristics of inner filling are still remained.

-

Sealed area is flat; over-melting phenomenon is contrlled.

-

With high frequency oscillation from ultrasonic, the liquid, oil, filling or plastic waste at sealing area is driven away. Sealing effect is more reliable.

This ultrasonic tube sealing machine is widely used in pharmaceutical, cosmetic, food and chemical industries etc., it is applicable in various aluminum plastic compound soft tube, plastic soft tube which pack all kind of Such as ointment, adhesives, AB glue, Neoprene, epoxy glue, skin cream, hair cream, boots oil, toothpaste and else liquid, lotions and cream etc.

Compared with heat sealing, the ultrasonic tube sealing has the following advantages:

* Fast Sealing, save time

* Sealing is nice looking, different shape sealing

* Lower power consumption, energy saving

Parameter of the 20Khz 2000W Ultrasonic Tube Welding System for Plastic Cosmetic Tube Sealing

Application:

1.It's applicable to toothpaste, cosmetic, pharmaceutical, food, industry product and other soft tube sealing.

2.The ultrasound output power is big enough to ensure the sealing quality of different kinds material and specifications soft tubes.

3.we can customize the horn depending on your requirements.

BENEFITS:

1.Digital generator Controlled

2.Strength of tube seal not compromised by presence of contaminants like ink,dye, powder, emulsion, etc.

3. Tube materials need not bepre-heated.Cost saving on-demand energy usage vs.continuous energy.

4. Seal strengths attainable to100% of the parent material.

5.Instantaneous solidification of bonded material.

6.Optional product&coding available