Products Details

20Khz 1000w Ultrasonic Cutting Machine For Hard and soft cheeses Cutting

Parameter | Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

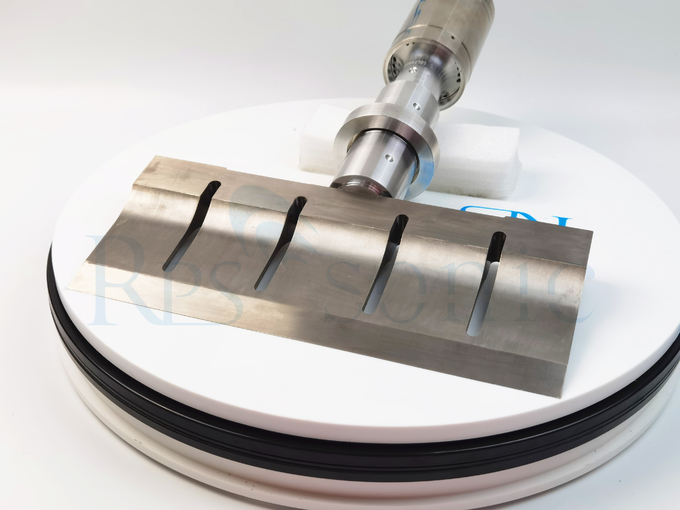

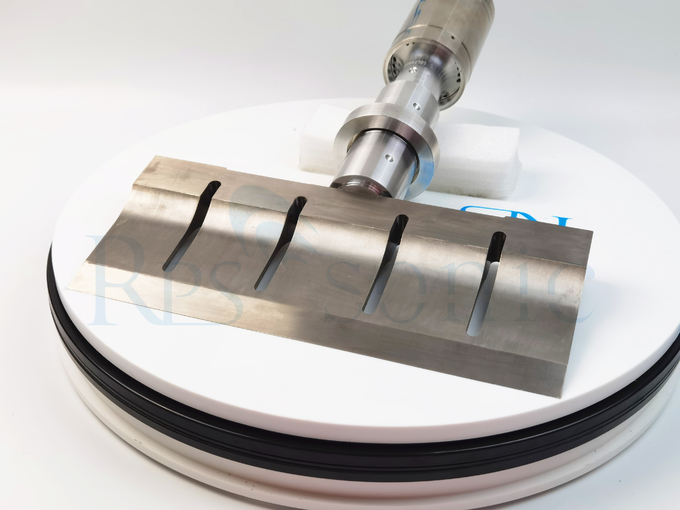

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 86mm in max |

| Horn amplitude | 10-40μm |

| Equipment weight | 8KG |

Introduction RPS-SONIC offers high quality ultrasonic food cutting components, including ultrasonic generators, transducers, guillotines and slitters. Ultrasonic food processing involves a vibrating knife (guillotine) producing a nearly frictionless surface that minimizes buildup on the blade surface. The ultrasonic blades cleanly cuts sticky products and inclusions such as nuts, raisins & morsels without displacement. Ultrasonic cutting is used by many of the world’s largest and most prestigious food producers. RPS-SONIC has been the world leader in ultrasonic food cutting technology for nearly 5 years. RPS-SONIC’s ultrasonic components are a widely used and proven technology. The “guillotine” blades are crafted in titanium and employ the latest FEA design technology for trouble free operation and reliability. What are ultrasonic waves?

Sound is a vibration that is transmitted through a medium, such as air, water, and metals. Ultrasonic waves are an “inaudible sound,” the frequency of which generally exceeds 20 kHz. A 20-kHz frequency means that a certain medium vibrates 20,000 times per second. What is the cutting done by the ultrasonic cutter?

The ultrasonic cutter vibrates its blade with an amplitude of 10 – 70 µm in the longitudinal direction. The vibration is microscopic, so it cannot be seen. The movement repeats 20,000 – 40,000 times per second (20 – 40 kHz). Because of this movement, the ultrasonic cutter can easily cut resin, rubber, nonwoven cloths, film, composite materials in which various products are superposed, and food. Features Cleaner cuts for outstanding aesthetics on layered products The ultrasonic blade produces a nearly frictionless surface which minimizes sticking of food products and deforming. This process produces clean cuts without smearing when cutting multiple layers. Reduce Scrap Reduce scrap by not crushing your products or damaging them during the cutting process. Inclusions such as nuts, raisins & dried fruit, are sliced with little to no displacement, even in a soft matrix. Consistent Result with Faster Process Ultrasonic technology provides larger processing window, cutting speeds can be increased substantially, and it is easy to adapt the Dukane ultrasonic cutting equipment to your existing production lines. Reduce Downtime No need to frequently clean blades when cutting sticky products Ultrasonic food cutting systems are often used to cut the following types of foods Hard and soft cheeses, including products containing pieces of nuts and fruit Sandwiches, wraps, and pizzas for catering industries Nougat, candy bars, granola bars and healthy snack bars Semi-frozen meats and fish Breads or cake products Pictures

How Do Ultrasonic Cutters Work,

auto parts welding machine,

ultrasonic aging,

ultrasonic spray coating,

use of probe sonicator,

Ultrasonic Cnc Machine,

Ultrasonic Spot Soldering Machinery,

Ultrasonic Cutter For Plastics,

high intensity ultrasonic processor,

Nanoparticles Dispersion Equipment,