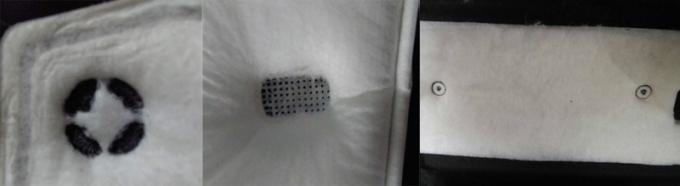

Ultrasonic spot welding machine for nonwoven fabric welding

Parameter| Item | Parameter | Advantage: | Application |

| 28Khz ultrasonic hand welder Straight type | ▪ 28Khz 800W ▪ Digital generator ▪ Horn customized ▪ Aluminum alloy&Steel & Titanium alloy ▪ Power Supply: 220v 50/60HZ | 1. light generator ,light hand welder.The generator 120*120*380, whole weight5KG, with generator 4kg, and the 28Khz hand welder 1kg, 35Khz hand welder 0.8kg. Suit for hand operate. 2. Special alloy metal housing, the housing of the hand-welder is light but firm, not easy to be deformed, longer it’d using life. 3. Digital generator, it can tracking the frequency itself, easy for operate. Output /welding time adjustable, suit for both hand operate and machine operate. | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 8mm in max. Straight type suit for both hand /machine operate. Gun type suit for hand operate. |

| 28Khz ultrasonic hand welder Gun type | |||

| 35Khz ultrasonic hand welder Straight type | ▪ 35Khz 500W ▪ Digital generator ▪ Horn customized ▪ Aluminum alloy&Steel & Titanium alloy ▪ Power Supply: 220v 50/60HZ | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 5mm in max. Straight type suit for both hand /machine operate. Gun type suit for hand operate. | |

| 35Khz ultrasonic hand welder Gun type | |||

| For better application , it is better share all the material information with me, the material, thickness, operate way, speed requirements before order . We also supply 20Khz 40Khz ultrasonic hand-weld welder. | |||

Basic Guidelines for Ultrasonic Spot Welding

- Low pressures

- Medium to high amplitudes

- Rigid support placed directly under the contact spot