Ultrasonic handheld spot welding machine 35Khz 500w for ultrasonic plastic welding

Parameter| Item | Parameter | Advantage | Application |

| 28Khz ultrasonic hand welder Straight type | ▪ 28Khz 800W ▪ Digital generator ▪ Horn customized ▪ Aluminum alloy&Steel & Titanium alloy ▪ Power Supply: 220v 50/60HZ | 1. light generator ,light hand welder.The generator 120*120*380, whole weight5KG, with generator 4kg, and the 28Khz hand welder 1kg, 35Khz hand welder 0.8kg. Suit for hand operate. 2. Special alloy metal housing, the housing of the hand-welder is light but firm, not easy to be deformed, longer it’d using life. 3. Digital generator, it can tracking the frequency itself, easy for operate. Output /welding time adjustable, suit for both hand operate and machine operate. | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 8mm in max. Straight type suit for both hand /machine operate. Gun type suit for hand operate. |

| 28Khz ultrasonic hand welder Gun type | |||

| 35Khz ultrasonic hand welder Straight type | ▪ 35Khz 500W ▪ Digital generator ▪ Horn customized ▪ Aluminum alloy&Steel & Titanium alloy ▪ Power Supply: 220v 50/60HZ | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 5mm in max. Straight type suit for both hand /machine operate. Gun type suit for hand operate. | |

| 35Khz ultrasonic hand welder Gun type | |||

| For better application , it is better share all the material information with me, the material, thickness, operate way, speed requirements before order . We also supply 20Khz 40Khz ultrasonic hand-weld welder. | |||

Principle of Handheld Ultrasonic Welder

Ultrasonic welding machine welding principle is generated by the generator 20KHz (or 15KHz) high-pressure, high-frequency signal, through the transducer system, the signal is converted to high-frequency mechanical vibration, added to the plastic workpiece, through the workpiece surface and internal The friction between the molecules and the temperature of the transfer to the interface, when the temperature reaches the melting point of the workpiece itself, so that the workpiece interface quickly melt, and then fill the gap between the interface; when the vibration stops, the workpiece at a certain pressure Cooling stereotypes, it will achieve the perfect welding.Ultrasonic Spot Welder Application

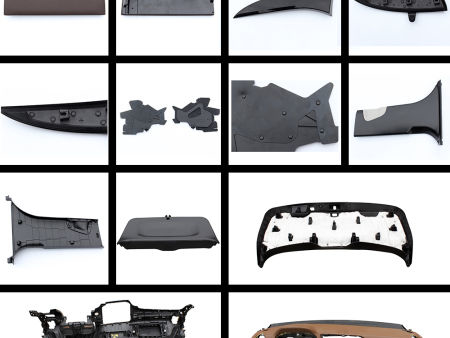

Portable spot welding machine is widely used in the apparel industry, the trademark industry, the automotive industry, plastic electronics, household goods industry. Clothing industry: underwear pants needle before the process, the ribbon elastic belt welding; can be used for point drilling. Trademark industry: weaving Mark with, India-Mark, and so on. Automotive industry: door noise cotton, wiper seat, engine cover, water tank cover and so on. Plastic electronic: small plastic pieces riveting and so on. Household goods industry: fiber cotton spot welding and so on.Advantages of portable ultrasonic welding machine

Hand-held ultrasonic welding is a fast, clean, safe and other advantages of plastic parts to achieve the advanced technology, the use of Japanese components, force large-scale reliable; multiple protection circuit for enterprises to provide efficient welding methods to reduce production costs.