Products Details

High power ultrasonic wire harness welding machine metal welding

Parameter | Power | 2000---6000W | Frequency | 20KHZ |

| Power supply | 220V | Gas source | 0.5kg |

| Way to control | Touch screen | Welding area range | 1mm---5mm |

| Welding mode | Automic | Welding time area | 0.01sec-999sec |

| Bracket size | 700LX600WX300H MM | Quality control | 1year |

| Generator size | 400LX280W220H MM | Whole weight | 60kg |

| Main component information | Transducer, mold, generator. |

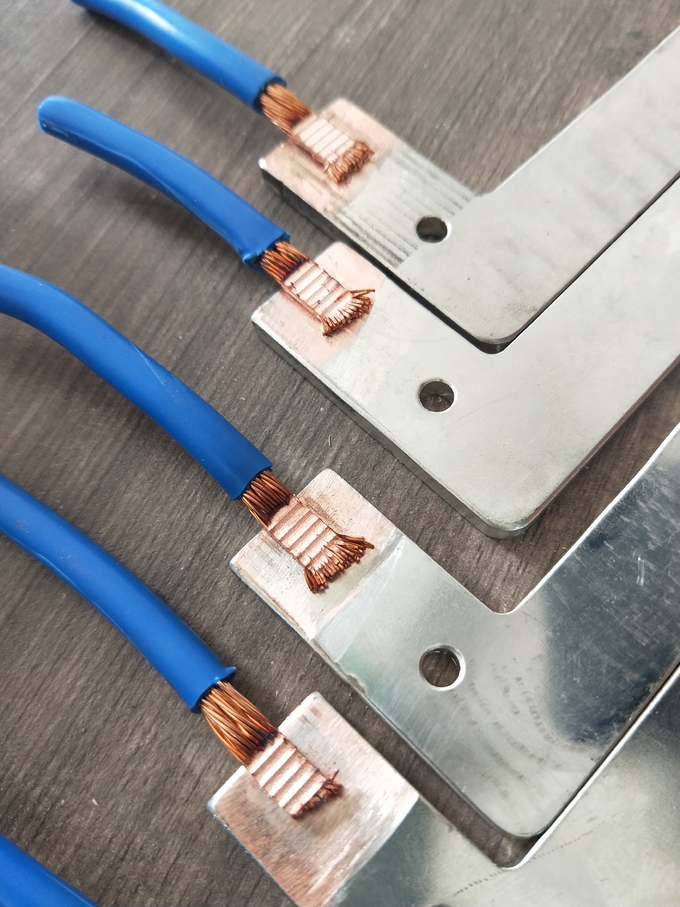

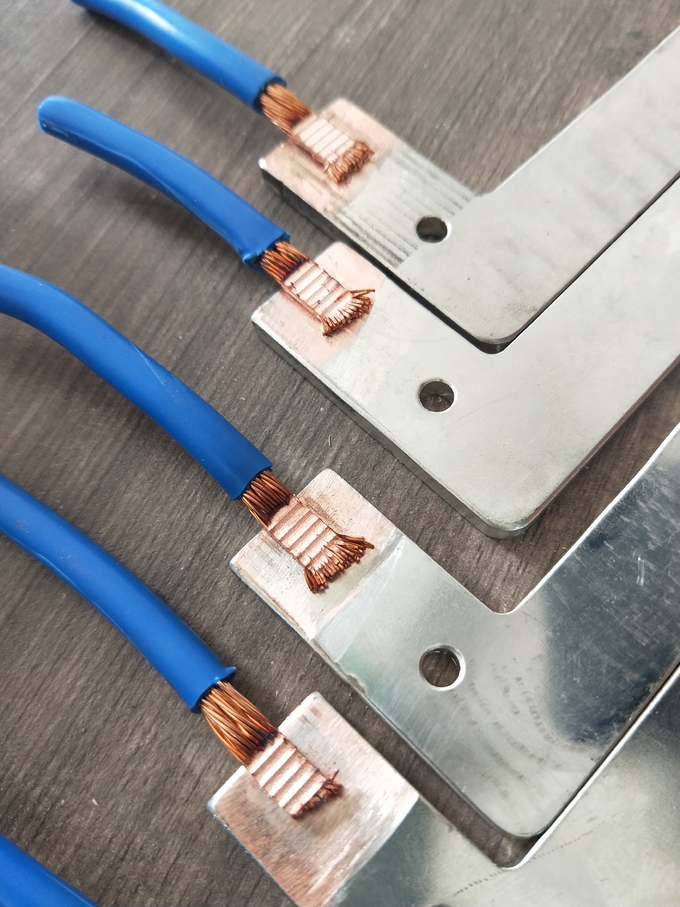

Description The ultrasonic spot welding welding system is a set of split ultrasonic metal welding system composed of generator, control box, touch screen, frame, transducer, amplitude modulator, welding head, base, tooling and mold. Ultrasonic metal welding is a special method that uses mechanical vibration energy of ultrasonic frequency to connect the same or dissimilar metals. When metal is ultrasonically welded, neither electric current nor high temperature heat source is applied to the workpiece, but under static pressure, the mechanical energy is transformed into internal energy, deformation energy and limited temperature rise. Solid phase welding occurs when the two base materials reach the recrystallization temperature. Therefore, it effectively overcomes the spatter and oxidation caused by resistance welding. Ultrasonic metal welding machine can perform single-point welding, multi-point welding and short strip welding on thin wire or sheet materials of non-ferrous metals such as copper, silver, aluminum, and nickel. It can be widely used in the welding of thyristor leads, fuse pieces, electrical leads, lithium battery pole pieces, and tabs. Ultrasonic metal welding uses high-frequency vibration waves to be transmitted to the metal surface to be welded. Under pressure, the two metal surfaces are rubbed against each other to form a fusion between molecular layers. The advantages are fast speed, energy saving, high fusion strength, good electrical conductivity, no sparks, and close to cold processing; the disadvantages are that the welded metal parts cannot be too thick (generally less than or equal to 5mm), the welding point cannot be too large, and it needs to be pressurized. Features 1. Welding without sparks, environmental protection and safety. 2. The welding material does not melt, and the metal is not fragile. 3. Low requirements on the welding metal surface, both oxidation and electroplating can be welded. 4. Ultrasonic welding time is short, without any flux, gas, solder. 5. After welding, the conductivity is good, and the resistivity is extremely low or nearly zero. Application 1. The wires are fused to each other, and one or more wires are fused to each other. 2. Ni-MH battery Ni-MH battery nickel mesh and nickel sheet mutual fusion and nickel sheet mutual fusion. 3. The wires are fused with famous electronic components, contacts and connectors. 4. Lithium battery and polymer battery copper foil and nickel sheet are mutually fused, and aluminum foil and aluminum sheet are mutually fused. 5. The sealing and cutting of the ultrasonic metal tube can be water-tight and air-tight. 6. Large heat sinks, heat exchange fins, bee Mutual melting of nest hearts. 7. High current contacts such as electromagnetic switches and non-fuse switches, and mutual fusion of dissimilar metal sheets.

digital generator,

Ultrasonic Aging Impact Gun,

spot welder,

Welding Machine Power Consumption,

nonwoven welding,

CO2 Laser Engraving Cutting Machine,

Portable Plastic Welding Machine,

Ultrasonic Harness Welding,

China Ultrasonic Metal Welding Machine and Ultrasonic Wire Splicer,

Machinery,