Strong output ultrasonic welding transducer design for pulse Welding

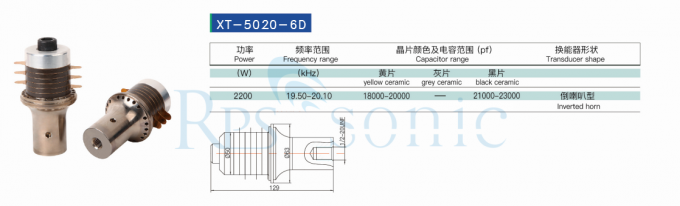

Parameter

Introduction

Ultrasonic weldingtransducer is the high-frequency mechanical vibration source and function of ultrasonic welding machine. It is to convert the electric energy or magnetic energy output by ultrasonic generator into mechanical vibration of the same frequency. There are currently two types of transducers for ultrasonic welding machines. One is a magnetostrictive transducer, the other is a piezoelectric ceramic transducer

Ultrasonic transducer parameters

Magnetostrictive transducers, due to their low efficiency and low cost performance, also require a DC polarized magnetic field, so ultrasonic welding machines are currently rarely used

The basic principle of piezoelectric ceramic transducers is based on the piezoelectric effect of crystal materials. This material is a piezoelectric crystal material. In ultrasonic welding machines, the production of piezoelectric ceramics is mainly used. This material occurs in mature fields. During deformation, an electric charge will appear on the surface of the piezoelectric ceramic crystal, and an electric field will be generated inside the crystal. On the contrary, when the crystal is subjected to an external electric field, the gold piece will deform. Effect, or reverse electrical effect.

The ultrasonic transducer is the core component of the ultrasonic vibration system. The design of the ultrasonic transducer is related to the efficiency, stability and life of the welding machine. Most piezoelectric ceramic transducers are used in the market. There are many different types of vibration, such as radial vibration mode, longitudinal composite vibration mode, shear vibration mode, and thickness vibration mode. Ultrasonic plastic welding machine working plastic parts, high frequency longitudinal vibration is required. The high-frequency vibration of the upper and lower molds of the workpiece melts the welding layer to obtain the welding effect.

Advantage

1. The piezoelectric ceramic chip adopts imported parts, and can give a strong and stable output.2. High efficiency, high mechanical quality factor, obtaining high electric-acoustic conversion efficiency work at the resonance frequency points.3. Large amplitude: optimization design by computer , vibration speed ratio is high .4. Large power,Under the action of prestressed screw, the energy of the piezoelectric ceramic to get maximum play;5. Good heat resistance, small harmonic impedance, low calorific value, using temperature range is wide.

Why RPS-SONIC TRANSDUCER:

1. Every transducer with a only tracking number, you can check the parameter from our saler no matter how long it passed.

2. All transducer with one year warranty.

3. Specialized in ultrasound for more than ten years

4. Every transducer with 24hours old testing before shipment.

5. Good packing, no packing problem during the 10 years exporting business.

6. Every customer will get purchase records and there are certain rewards after accumulation

Service and shipment

- Warranty one year for transducer.

- You can contact us for technical inquiry any time.

- We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

- We supply customized products service for small quantity also.

- Shipment by FED-EX /DHL/UPS/TNT

Advantages of piezoelectric ceramic transducers:

1. Most of the ceramic components have large compressive strength, and the central screw is used for protection. On the other hand, it is enhanced when the environmental strength changes, and the stability of the transducer is guaranteed. In order to avoid the crack caused by the ceramic account, because the disadvantage of the ceramic material is the small allowable tensile stress

2. Because the middle collective part is composed of a group of electrode shafts on the axially polarized rings on both ends, the largest effective coupling coefficient k33 can be used.

3. There are options for the number of rings and connection methods, so that the transducer can be designed with a wide impedance and frequency range.

4. Changing the material size of the head and tail metal cover plates can control the transducer's bandwidth, forward and backward vibration speed ratio, and effective electromechanical coupling coefficient.