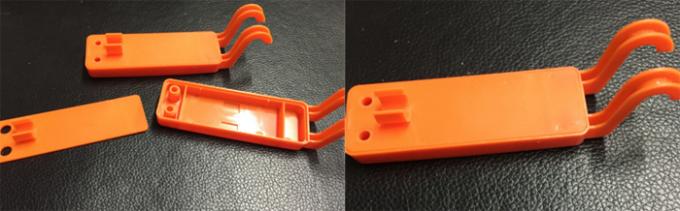

Effective waterproof ultrasonic welding electronic components 20khz

WHAT IS ULTRASONIC WELDING?

In simple terms, ultrasonic welding uses high frequency vibrations to heat and bond two parts that are touching under pressure. These high frequency vibrations exceed the limit of human hearing in most cases. The range of human hearing is from 20 Hz to 20 kHz while ultrasonic frequencies utilized in these welders typically range from 15 kHz to 75 kHz. The technique was patented in the 60’s and first used in the toy industry. Since then, the technology continues to advance and is used in industries such as medical, electronics, packaging, and automotive. Ultrasonic welding can be used for plastics as well as metals, but this article will primarily focus on plastic welding. To better understand ultrasonic welding let’s examine the components of a welder.Welding with ultrasound is a process of combining thermoplastics or metals using the heat created through mechanical actions that operate at a high-frequency. An electrical energy with high-frequency is produced and is converted into this high-frequency mechanical motion. Applied force is used in conjunction with the mechanical motion to produce heat friction at the mating surfaces or joint areas of the metals or thermoplastics. This heat friction causes the parts to melt together, forming a molecular bond that is strengthened once the materials cool back down. In the case of metals, the heat friction raises the metal surfaces’ temperatures to around one-third of its melting point. Rather than melting the metals, the heat friction removes films and metal oxides from the metal surfaces, permitting the metal atoms to move between the surfaces and fuse the metals together.

Function

1. Frequency auto-chasing: intelligent control system, frequency auto tracking.

2. amplitude adjust Infinitely : amplitude adjust Infinitely , amplitude increase and decrease by 5%;

3. intelligent protection: frequency offset protection, output overloading protection, mold damage protection;

4. electrical components: all pneumatic components and main electronic components of the machine are imported from Germany and Japan;

5. fuselage structure: the frame of the machine adopt special steel structure and made by precision cast aluminum CNC machining processing , the frame is more precise and more stable

Parameter:

| Frequency | 15Khz | 20KHz |

| Generator | 3000W/5000W | 2000W/3000W |

| Welding model | Time model energy model, power model, depth model | |

| Distance micro-adjustment | 20-100mm Precision:0.01 mm | |

| The height of the frame in max | 280mm | |

| Input Voltage | 220V/110V | |

ApplicationsUltrasonic assembly is the method of choice for many applications in the automotive, appliance, medical, textile, packaging, toy and electronics markets, among others. The basic advantages of ultrasonic assembly - fast, strong, clean and reliable welds - are common to all markets.

| Appliance | In this high-volume market, hermeticity, strength and also cosmetic appearance are important. Applications include: steam iron, pump housing, vacuum cleaner wand, and dishwasher spray arm. |

| Automotive | Hermetic seals in applications such as lenses, filters and valves. Other applications include: glove box door, instrument cluster, air diverter and mass airflow sensor. |

| Business | "Clean" assemblies with reduced particulate matter are produced on information storage discs. Other applications include the assembly for ribbon cartridges, and audio and video cassettes. |

| Consumer | Precision welding, staking and forming operations are used in the manufacture of the Swatch®. |

| Electrical | Multiple staking and inserting applications are often automated for high-volume production requirements with consistent reliability. Applications include: terminal blocks, connectors, switches (e.g. toggle, dip, rotary quick and diaphragm), and bobbin assemblies. |

| Medical | Non-contamination and the ability to be operated in a clean room are as important as the strength of the weld. Reliable, repeatable assemblies for critical life-support devices are produced with new capabilities in process control. Applications include: arterial filter, cardiometry reservoir, blood/gas filter, face mask and IV spike/filter. |

| Packaging | From aseptic packages to toothpaste tubes, the ability of ultrasonic assembly to seal through product contamination in the joint area is a major advantage. In addition to good cosmetic appearance, ultrasonic assembly provides tamper-evident seals for blister packs. Applications include: condiment dispenser, blister package, juice pouch, juice carton and plastic coated paper cups. |

| Toys | In this highly competitive industry, the elimination of adhesives, screws and solvents, or other consumables is a bonus added to strong, safe, flash-free assemblies. |

RFID card welding