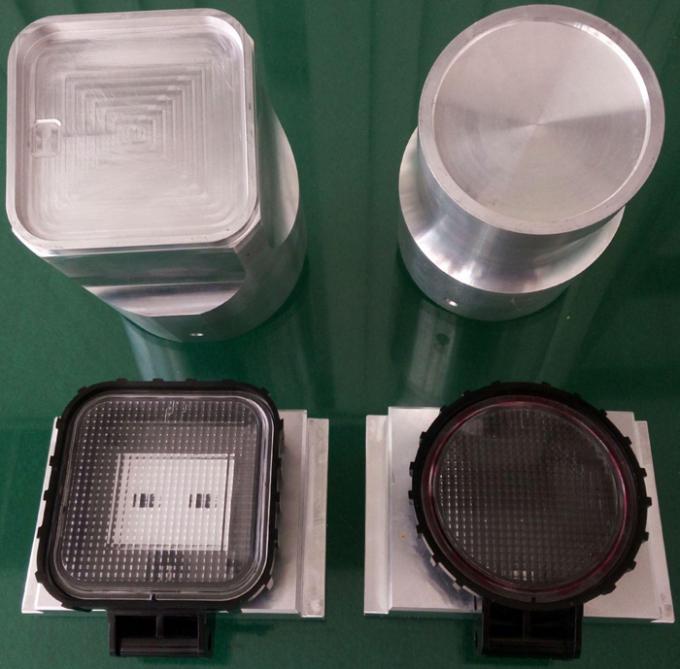

Rectangle and round ultrasonic welding horn design guide supply

Parameter:

Please check our horn dimension as follows:

| 15k rectangle horn | Steel | Aluminum alloy | Titanium alloy | |||

| Length(mm) | width(mm) | length(mm) | width(mm) | length(mm) | width(mm) | |

| 90 | 12-30 | 70 | 12-30 | 70 | 20-30 | |

| 120 | 12-30 | 80 | 12-30 | 90 | 20-30 | |

| 155 | 12-30 | 90 | 12-30 | 155 | 20-30 | |

| 210 | 20-30 | 120 | 15-30 | 180 | 20-30 | |

| 270 | 20-30 | 160 | 15-30 | 210 | 20-30 | |

| 320 | 20-30 | 210 | 15-30 | 270 | 20-30 | |

| 270 | 15-30 | |||||

| 320 | 15-30 | |||||

| 350 | 15-30 | |||||

| 15k Circle horn | Steel | Aluminum alloy | Titanium alloy | |||

| diameter | diameter | diameter | ||||

| 30 | 30 | 30 | ||||

| 50 | 50 | 50 | ||||

| 65 | 65 | 65 | ||||

| 75 | 75 | |||||

| 85 | 85 | |||||

| 90 | 90 | |||||

| 20k rectangle horn | Steel | Aluminum alloy | Titanium alloy | |||

| Length(mm) | width(mm) | length(mm) | width(mm) | length(mm) | width(mm) | |

| 50 | 15-25 | 50 | 10-25 | 90 | 10-25 | |

| 60 | 15-25 | 55 | 10-25 | 95 | 10-25 | |

| 65 | 15-25 | 60 | 10-25 | 100 | 10-25 | |

| 70 | 15-25 | 70 | 10-25 | 115 | 10-25 | |

| 90 | 15-25 | 90 | 10-25 | 120 | 10-25 | |

| 95 | 15-25 | 95 | 10-25 | 140 | 10-25 | |

| 115 | 15-25 | 115 | 15-25 | 160 | 10-25 | |

| 155 | 15-25 | 175 | 15-25 | 175 | 10-25 | |

| 175 | 15-25 | 200 | 15-25 | 200 | 10-25 | |

| 200 | 15-25 | 210 | 15-25 | 210 | 10-25 | |

| 210 | 15-25 | 270 | 15-25 | 270 | 10-25 | |

| 270 | 15-25 | 300 | 15-25 | 300 | 10-25 | |

| 20k circle horn | steel | Aluminum alloy | Titanium alloy | |||

| diameter | diameter | diameter | ||||

| 30 | 20 | 20 | ||||

| 35 | 35 | 35 | ||||

| 40 | 40 | 40 | ||||

| 45 | 45 | 45 | ||||

| 50 | 50 | 50 | ||||

| 54 | 54 | 54 | ||||

| 65 | 65 | 65 | ||||

| 75 | ||||||

Horn or Sonotrode. The ultrasonic welding horn is sometimes more commonly referred to as a sonotrode outside the United States. The ultrasonic weldinghorn receives vibrations from the booster and further amplifies or attenuates the amplitude of the acoustic waves. The ultrasonic welding horn is also responsible for applying these vibrations to the parts being welded by direct contact. In a plastic welder, the ultrasonic weldinghorn and booster vibrate axially at the operational frequency set by the power supply. The ultrasonic welding horn contacts the top plastic piece and applies these vibrations perpendicular to the surface of the part. In contrast, metal welder horns lay horizontal, and the vibrations are applied parallel to the parts’ surface. The ultrasonic welding horn is uniquely engineered to vibrate with its ends moving in opposite directions at all times while the welding horn’s center stays in place. By multiplying the converter’s output amplitude by the gain of the booster and by the gain of the wedling horn, you can find the stack’s effective output amplitude applied to the part. Titanium is the material of choice for horn construction due to its mechanical properties such as high fatigue strength and hardness, but economical aluminum and steel horns also exist for the right application. There are multitudes of welding horn shapes that each have their own unique application, and custom ultrasonic welding horns can be made for special applications. A circular horn for example is useful when the parts are to be welded on their circumference. Before a horn can apply the vibration to the workpiece, it must first be lowered into place.

How to design an ultrasonic welding horn:

1. Depending on the application: we will have a general design direction according to different applications, such as ultrasonic cutting, ultrasonic welding, ultrasonic sealing

2. Design the horn darwing, Design a reasonable ultrasonic horn according to the size of the welding & cutting area, and issue 3D modeling graphics

3. FEA analysis the horn to confirm best result

4. Make the horn

5. Surface treatment

Why RPS-SONIC HORN:

1. Every horn will be designed by FEA system , so that to confirm theEnd face of the ultrasonic horn with uniform force

2. All ultrasonic horns with three months warranty.

3. Specialized in high power ultrasonic for more than ten years

4. Every ultrasonic hornwith 24hours old testing before shipment.

5. Good packing, no packing problem during the 10 years exporting business.

6. Every customer will get purchase records and there are certain rewards after accumulation

Service and shipment

- Warranty one year for transducer.

- You can contact us for technical inquiry any time.

- We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

- We supply customized products service for small quantity also.

- Shipment by FED-EX /DHL/UPS/TNT