Customized high power Geogrid ultrasonic welding horn Aluminum alloy

Parameter:

Please check our horn dimension as follows:

| 15k rectangle horn | Steel | Aluminum alloy | Titanium alloy | |||

| Length(mm) | width(mm) | length(mm) | width(mm) | length(mm) | width(mm) | |

| 90 | 12-30 | 70 | 12-30 | 70 | 20-30 | |

| 120 | 12-30 | 80 | 12-30 | 90 | 20-30 | |

| 155 | 12-30 | 90 | 12-30 | 155 | 20-30 | |

| 210 | 20-30 | 120 | 15-30 | 180 | 20-30 | |

| 270 | 20-30 | 160 | 15-30 | 210 | 20-30 | |

| 320 | 20-30 | 210 | 15-30 | 270 | 20-30 | |

| 270 | 15-30 | |||||

| 320 | 15-30 | |||||

| 350 | 15-30 | |||||

| 15k Circle horn | Steel | Aluminum alloy | Titanium alloy | |||

| diameter | diameter | diameter | ||||

| 30 | 30 | 30 | ||||

| 50 | 50 | 50 | ||||

| 65 | 65 | 65 | ||||

| 75 | 75 | |||||

| 85 | 85 | |||||

| 90 | 90 | |||||

| 20krectangle horn | Steel | Aluminum alloy | Titanium alloy | |||

| Length(mm) | width(mm) | length(mm) | width(mm) | length(mm) | width(mm) | |

| 50 | 15-25 | 50 | 10-25 | 90 | 10-25 | |

| 60 | 15-25 | 55 | 10-25 | 95 | 10-25 | |

| 65 | 15-25 | 60 | 10-25 | 100 | 10-25 | |

| 70 | 15-25 | 70 | 10-25 | 115 | 10-25 | |

| 90 | 15-25 | 90 | 10-25 | 120 | 10-25 | |

| 95 | 15-25 | 95 | 10-25 | 140 | 10-25 | |

| 115 | 15-25 | 115 | 15-25 | 160 | 10-25 | |

| 155 | 15-25 | 175 | 15-25 | 175 | 10-25 | |

| 175 | 15-25 | 200 | 15-25 | 200 | 10-25 | |

| 200 | 15-25 | 210 | 15-25 | 210 | 10-25 | |

| 210 | 15-25 | 270 | 15-25 | 270 | 10-25 | |

| 270 | 15-25 | 300 | 15-25 | 300 | 10-25 | |

| 20k circle horn | steel | Aluminum alloy | Titanium alloy | |||

| diameter | diameter | diameter | ||||

| 30 | 20 | 20 | ||||

| 35 | 35 | 35 | ||||

| 40 | 40 | 40 | ||||

| 45 | 45 | 45 | ||||

| 50 | 50 | 50 | ||||

| 54 | 54 | 54 | ||||

| 65 | 65 | 65 | ||||

| 75 | ||||||

The utility model relates to a welding device for a geogrid ultrasonic welding machine, and belongs to the technical field of geogrid ultrasonic welding machines. The welding device comprises welding head(s) and aluminum die head(s) which are matched with each other, wherein each aluminum die head has an integral structure; the at least one welding head is arranged above the aluminum die head in a corresponding way; the top of each welding head is provided with a lifting mechanism used for driving the welding head to move up and down; the top of each lifting mechanism is arranged on a sliding block plate; a sliding connection plate is corresponding to each sliding block plate, and the sliding block plate is connected with the sliding connection plate in a sliding fit way; each sliding block plate is provided with a fixing mechanism used for locking the sliding block plate and the corresponding sliding connection plate. According to the welding device, the aluminum die head(s) is/ are arranged at the lower part(s) of the welding head(s), and each welding head is provided with the lifting mechanism, so that two grid strips at each cross point on the same straight line can be well guaranteed to be compressed when the welding device is in use, the welding quality is guaranteed, the production efficiency is increased, and the production cost is lowered.

The key factors of the ultrasonic welding horn manufacturing of the ultrasonic welding horn: The vibration mode of the ultrasonic welding horn needs to be a resonance mode with uniform amplitude distribution and scattered internal alternating stress. The smaller the value, the better. The vibration state affects the life and welding ability of the ultrasonic welding horn, and it will cause serious damage to the ultrasonic system. Therefore, it is very important to determine whether the vibration state of the ultrasonic welding horn is normal. In the past, the planning and manufacturing of ultrasonic welding horns were mostly based on experience, and the quality of the vibration state was judged. In addition to the value analysis of the ammeter and voltmeter on HORN CHECK, the vibration state of the ultrasonic mold was mainly measured by hand. Accumulated experience over a suitable period of time is necessary for correct identification, so the vibration state test should be based on instrumental data and supplemented by hand feeling tests. Ultrasonic Welding horn

Why RPS-SONIC HORN:

1. Every horn will be designed by FEA system , so that to confirm theEnd face of the ultrasonic horn with uniform force

2. All ultrasonic horns with three months warranty.

3. Specialized in high power ultrasonic for more than ten years.

4. Every ultrasonic hornwith 24hours old testing before shipment.

5. Good packing, no packing problem during the 10 years exporting business.

6. Every customer will get purchase records and there are certain rewards after accumulation.

Service and shipment

- Warranty one year for transducer.

- You can contact us for technical inquiry any time.

- We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

- We supply customized products service for small quantity also.

- Shipment by FED-EX /DHL/UPS/TNT

Technical requirements for ultrasonic geogrid welding

1. The thickness of the geogrid should be thin, usually about 3.0mm, for paving;

2. The grid grid size should be 0.5 to 1.0 times the aggregate particle size. This project adopts 25.4 × 25.4mm;

3. The tensile strength of the geogrid should be selected to a large value, 50KN / M or more in the longitudinal direction and 50KN / M or more in the transverse direction, and the deformation resistance is strong;

4. Elongation is less than 4%;

5. The gel content is greater than or equal to 20%;

6. The geogrid is self-adhesive, with a width of 2m and temperature resistance of -100 to 280 degrees Celsius.

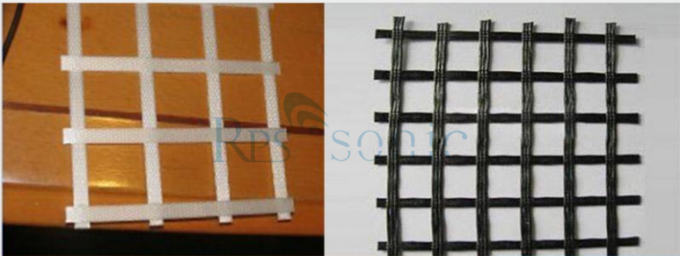

Geogrid be widely used in construction, foundation engineering, road, mine protection, and slope protection of the Haifang River embankment, etc., and the application field is extremely wide.

Based on the utilization of existing social resources and maximizing the competitive advantage of the product, the project is currently positioned for the protection of coal mine lanes. The weaknesses of the current protection network of the coal mine system and the market capacity have been explained in depth, and because of the huge commercial profits and development opportunities in it, this product selection should be ideal for expansion in this industry.