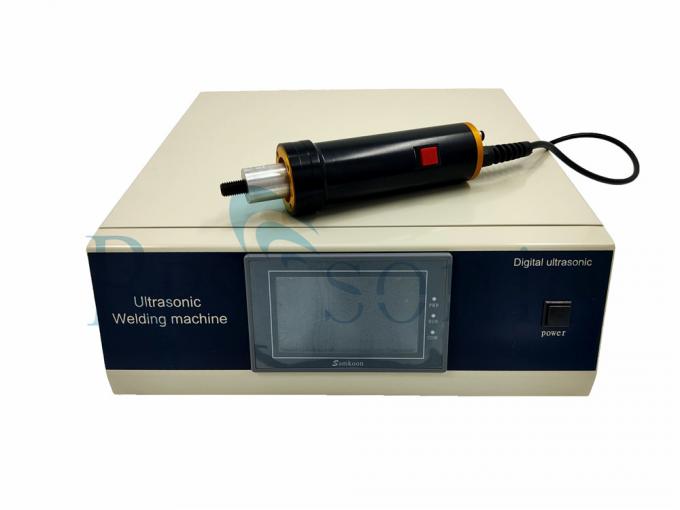

Compact Portable Ultrasonic welding Machine Automobile Industry

| Frequency: | 30khz | Power: | 1000W |

|---|---|---|---|

| Horn: | Customized | Horn Material: | Alumium Alloy Or Titanium Alloy |

| Generator: | Digital 4200 | Weight: | 13kg In Totall |

| High Light: | portable ultrasonic welder,handheld ultrasonic welder | ||

Compact Portable Ultrasonic welding Machine Automobile

Industry

Introduction:

Ultrasonic application range: Ultrasonic welding machine is mainly used for the secondary connection of thermoplastics. Compared with other traditional processes (such as gluing, electric perm or screw fastening, etc.), it has high production efficiency, good welding quality, environmental protection and energy saving. advantage. Ultrasonic plastic welding equipment is widely used in medical equipment, packaging, auto parts, fishing gear and other industries, such as disposable infusion filters and plasma separation cups, ziplock bags, plastic wine bottle caps, dishwasher water wheels, plastic toys, car lights, Plastic fake fishing lures, welding of charger shells and mobile phone straps, welding of lighter shells, etc., manufacturing body plastic parts, automobile doors, automobile instruments, lights and mirrors, sun visors, interior parts, filters, reflectors Materials, reflective road studs, bumpers, cables, plastic filters for motorcycles, radiators, brake fluid tanks, oil cups, water tanks, fuel tanks, air ducts, exhaust gas purifiers, tray filter plates; plastic electronics: prepaid Water meter, electricity meter, communication equipment, cordless phone, mobile phone accessories, mobile phone case, battery case, charger, valve-controlled sealed maintenance lead-acid battery, 3-inch floppy disk, U disk, SD card, CF card, USB connector, Bluetooth; Toys and stationery: folders, photo albums, folding boxes, PP hollow boards, pen sleeves, ink cartridges, toner cartridges, medical daily use: watches, kitchenware, oral liquid bottle caps, drip bottle caps, mobile phone accessories, golden soft brushes, daily necessities, hygiene Supplies, children's products, air mattresses, hangers, knife handles, gardening supplies, kitchenware and sanitary ware, shower heads, golden soft brushes, shower heads, anti-counterfeiting caps, cosmetic caps, coffee pots, washing machines, air dehumidifiers, electric irons , Electric kettle, vacuum cleaner, speaker metal cover and civil grille, etc. According to the research, the strength of the joint increases at a decreasing rate as the welding time increases, and from a certain moment, its value does not change. In our research, we did not find such stability for time. In a certain period of time at the beginning, no new joints are generally formed. Ultrasonic vibration destroys the film on the surface and removes some parts of it. The contact surface between the two weldments becomes bright. In addition to the cleaned surface, in many cases, splash-like forms can be found Extruded oxide film. This phenomenon is particularly obvious when there is no pre-cleaned copper and titanium on the surface of the weldment. In addition to the effect on the surface film, the temperature rises very rapidly at the beginning of the ultrasonic welding process. This is another feature. When the surface is in close contact and there is no surface film on the friction surface, the matrix metal molecules will be generated. Of glue. The working principle of ultrasonic welding machine. Ultrasonic welding machine has a center frequency, such as 20KHz, 40KHz, and the working frequency of the welding machine is mainly determined by the mechanical resonance frequency of the transducer, horn, and welding head. The frequency of the generator is adjusted according to the mechanical resonance frequency to achieve consistency, so that the welding head works in a resonant state, and each part is designed as a half-wavelength resonant body. As mentioned above, because the ultrasonic welding machine often works under high-frequency vibration, it should try to maintain a symmetrical design to avoid the unbalanced stress and lateral vibration caused by the asymmetry of sound wave transmission. Unbalanced vibration can cause The welding is horn and broken.