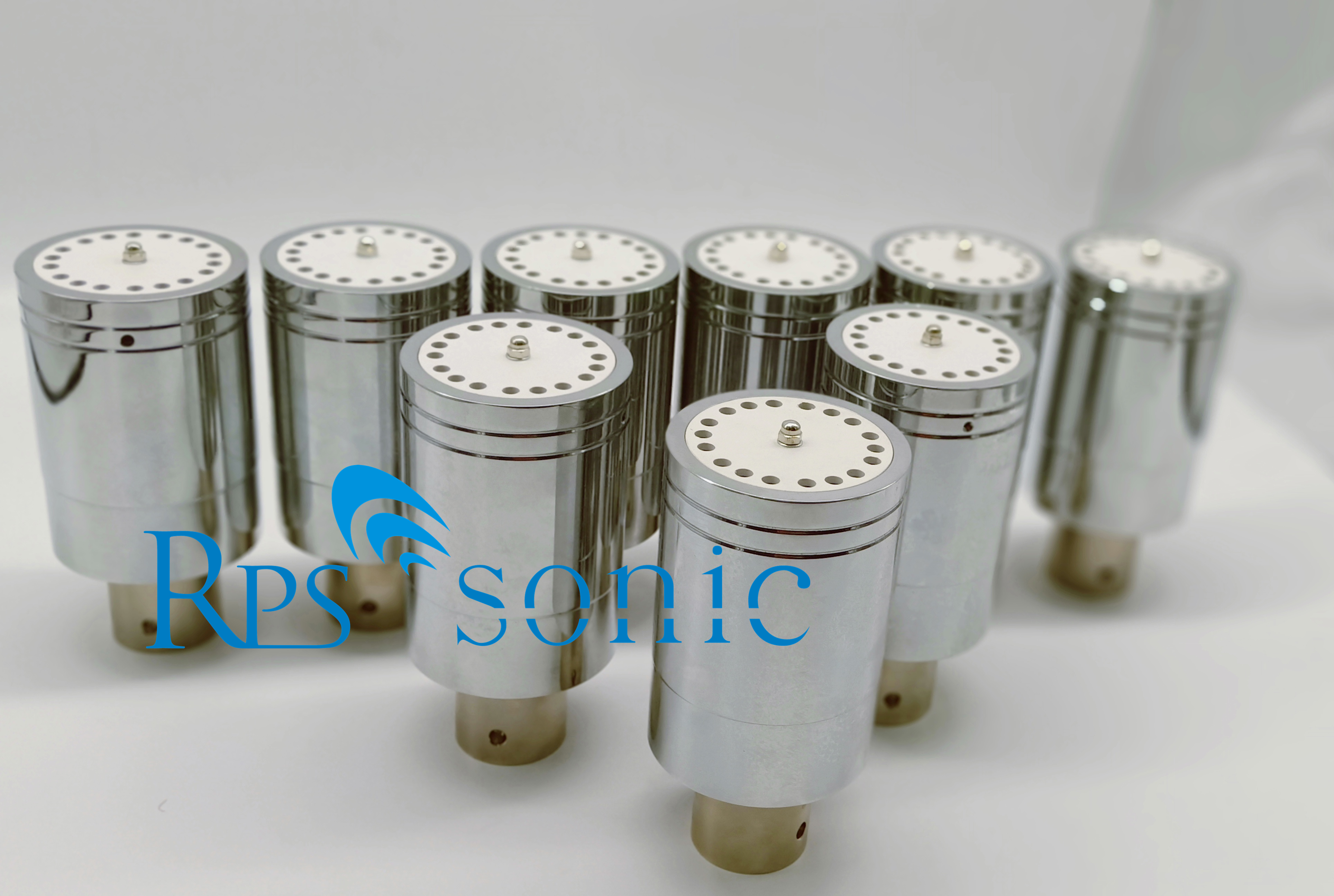

Branson Alternative 20kHz Ultrasonic Welding Transducer 3300w For Plastic Welding

Parameter| Model | RPS-CJ20 |

| Frequency | 20 khz |

| Output power | 3300 watt |

| Joint bolt | 1/2-20 UNF |

| Ceramic disc Diameter | 50 mm |

| Quantity of Ceramic discs | 6 pcs |

| Capacitance | 19-21 nf |

| Amplitude | 20 um |

| Application | welding machine |