Aluminum Alloy Horn Ultrasonic Spot Welder 35khz 800w Description

| Frequency: | 35khz | Power: | 800w |

|---|---|---|---|

| Color: | White | Horn Material: | Aluminum Alloy |

| Weight: | 5kg In Totall | ||

| High Light: | 800w ultrasonic spot welder,35khz ultrasonic spot welder,Aluminum Horn Ultrasonic Spot Welder | ||

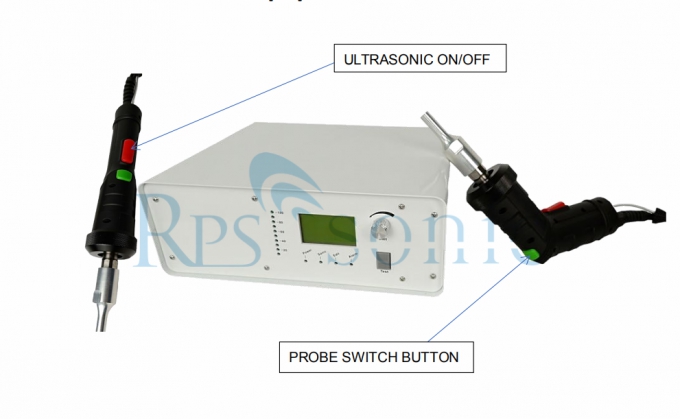

Aluminum Alloy Horn Ultrasonic Spot Welder 35khz 800w

Introduction:Ultrasonic plastic welding machine is a welding equipment developed in the field of plastic welding, the industry is referred to as the ultrasonic plastic welding machine for short. Ultrasonic welding equipment is a high-tech technology for welding cooked plastic products. All kinds of cooked plastic parts can be treated with ultrasonic welding. When welding plastic products, do not add any adhesives, fillers or solvents, nor consume a large amount of heat .It has the advantages of easy operation, fast welding speed, high welding strength and high production efficiency. Therefore, the ultrasonic welding technology is more and more widely used.

Parameter:

| Item | Parameter | Advantage: | Application |

| 28Khz ultrasonic hand welderStraight type | ▪ 28Khz 800W▪ Digital generator▪ Horn customized▪ Aluminum alloy&Steel & Titanium alloy▪ Power Supply: 220v 50/60HZ | 1. light generator ,light hand welder.The generator 120*120*380, whole weight5KG, with generator 4kg, and the 28Khz hand welder 1kg, 35Khz hand welder 0.8kg. Suit for hand operate.2. Special alloy metal housing, the housing of the hand-welder is light but firm, not easy to be deformed, longer it'd using life.3. Digital generator, it can tracking the frequency itself, easy for operate. Output /welding time adjustable, suit for both hand operate and machine operate. | PP PVC Fabric woven PE ABSPS Nylon PU PET All Thermoplastic material, the thickness 8mm in max.Straight type suit for both hand /machine operate.Gun type suit for hand operate. |

| 28Khz ultrasonic hand welderGun type | |||

| 35Khz ultrasonic hand welderStraight type | ▪ 35Khz 500W▪ Digital generator▪ Horn customized▪ Aluminum alloy&Steel & Titanium alloy▪ Power Supply: 220v 50/60HZ | PP PVC Fabric woven PE ABSPS Nylon PU PET All Thermoplastic material, the thickness 5mm in max.Straight type suit for both hand /machine operate.Gun type suit for hand operate. | |

| 35Khz ultrasonic hand welderGun type | |||

| For better application , it is better share all the material information with me, the material, thickness, operate way, speed requirements before order .We also supply 20Khz 40Khz ultrasonic hand-weld welder. | |||

Ultrasonic plastic welding machine

Ultrasonic welding machine is suitable for: mobile phone case welding, charger welding, CF card, battery case welding, U disk welding, SD card welding, adapter welding, USB connection program welding, Bluetooth welding, folder welding, photo album welding, watch welding, Kitchenware welding, mobile phone trim welding, gold soft brush welding, folding box welding, PP hollow board welding, pen sleeve welding, ink cartridge welding.

Medical products: Ultrasonic plastic welding equipment is widely used in medical plasma separation cups, flow meters, mobile urinals, culture bottles, urinary testers, medical box welding machines.

Electronic industry: The special ultrasonic plastic welding machine for the electronic industry has the advantages of easy operation, fast welding speed, high welding strength and high production efficiency. In the past decade, ultrasonic welding technology has been increasingly used in the plastic welding industry.

Do not add any adhesives, fillers or solvents during the ultrasonic welding of electronic products, and do not consume a lot of heat sources.

Advantages: small size, simple operation, fast cleaning; adopts modular integrated circuits, strong power output; built-in automatic protection circuit, safe to use, stable and reliable work. The welding surface is firm, strong, beautiful and environmentally friendly. The handheld ultrasonic welding machine can replace different ultrasonic welding heads according to the size of the riveting point and welding requirements of the products to be welded. It is fast and convenient, and the cost is much lower than that of the special ultrasonic welding machine for automobile door panels. Meet customer needs in many ways.