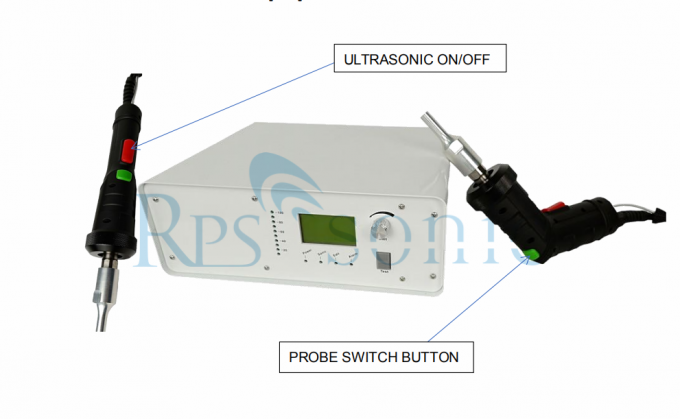

800W Ultrasonic Spot Welding Machine Low Energy Consumption

Description

| Frequency: | 35khz | Power: | 800W |

|---|---|---|---|

| Horn: | Customized | Horn Material: | Alumium Alloy |

| Generator: | Digital Generator | Weight: | 5kg In Totall |

| High Light: | portable ultrasonic welder,handheld ultrasonic welder | ||

800W Ultrasonic Spot Welding Machine Low Energy Consumption

Introduction:

Ultrasonic plastic welding machine is a welding equipment developed in the field of plastic welding, the industry is referred to as the ultrasonic plastic welding machine for short. Ultrasonic welding equipment is a high-tech technology for welding cooked plastic products. All kinds of cooked plastic parts can be treated with ultrasonic welding. When welding plastic products, do not add any adhesives, fillers or solvents, nor consume a large amount of heat .It has the advantages of easy operation, fast welding speed, high welding strength and high production efficiency. Therefore, the ultrasonic welding technology is more and more widely used.

Parameter:

Portable ultrasonic spot welding machine, handheld ultrasonic welding machine usage: Ultrasonic spot welding: Use the small welding head of the ultrasonic machine to divide the two plastic products into multi-point welding, or press the entire row of tooth-shaped welding heads directly on the two plastic workpieces to achieve the effect of ultrasonic spot welding. Ultrasonic Spot Welder Ultrasonic molding: The plastic workpiece is instantly melted and formed by an ultrasonic machine. When the plastic solidifies, the plastic made of metal or other materials can be firmly fixed. Ultrasonic spot welding machine Ultrasonic welding: Ultrasonic vibration transfers the ultrasonic energy and the ultrasonic welding mold to the plastic surface for welding, thereby generating local high temperature and melting the plastic surface. In the ultrasonic welding machine, two pieces of plastic can be welded under 70% pressure, which is beautiful and firm. Ultrasonic plastic welding machine Ultrasonic implantation: Put nuts, screws or other metals into plastic workpieces. Ultrasonic energy is transferred to the metal through the ultrasonic machine. After high-speed vibration and heat generation, the metal object is directly embedded in the plastic under the pressure of the ultrasonic machine. Ultrasonic Plastic Spot Welder Ultrasonic riveting: metal and plastic or two pieces of plastic with different properties are joined together. The ultrasonic riveting method can make the welded parts less brittle, beautiful and firm. Ultrasonic riveting machine Ultrasonic ablation: The special design method of ultrasonic welding mold and base tool can achieve the effect of ultrasonic ablation of cloth or plastic through ultrasonic transmission. Principle of ultrasonic plastic welding machine: Ultrasonic generator converts 50/60 Hz electric current into 15, 20, 35 kHz electric energy. The converted high-frequency electric energy is passed through the ultrasonic transducer, and then converted into mechanical motion of the same frequency for the second time, and then transmitted to the ultrasonic welding head through a set of amplitude modulation device that can change the amplitude. The welding head will receive ultrasonic vibration energy, which is transferred to the joint of the workpiece to be welded. The ultrasonic vibration energy in this area is converted into heat energy through friction, thereby melting the plastic. The welding time and welding head pressure of the ultrasonic plastic welding machine are adjustable, and the amplitude is determined by the sensor and the horn.