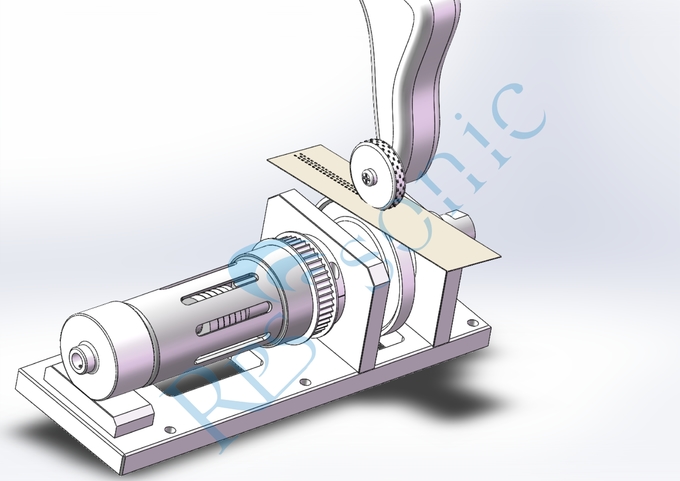

The core technology of the ultrasonic seamless stitching system lies in the use of a disc-shaped welding head for seam welding, which ingeniously converts the longitudinal vibration of the transducer into a radial vibration of the disc-shaped welding head radiating 360° outward in the diameter direction. And different from the traditional lace machine, the traditional lace machine is generally composed of a flat tool head and a patterned roller. Because the tool head is stationary, it is easy to cause deformation and wrinkling of fabrics such as fabrics during work. The seamless sewing machine uses two discs to vibrate to sew the cloth, which solves this problem well. This not only greatly reduces the volume of the vibration system itself, but also greatly reduces the installation size, the whole machine is beautiful, the volume is reduced, and the weight is greatly reduced.