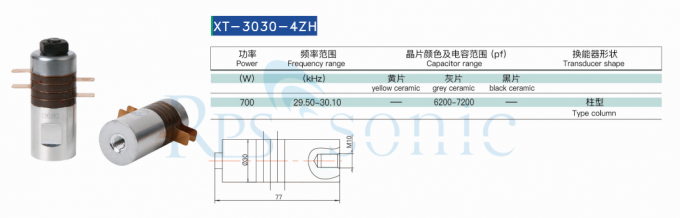

30khz Low impedance ultrasonic welding transducer For sealing

Parameter

How to selectultrasonic welding transducers depending on thefollowing parameters:① Resonant frequency: F, Unit: KHzThe frequency refers to the frequency measured by a transmission line method using a Ultrasonic frequency generator, a millivolt meter, or the frequency measured by a similar instrument such as an impedance characteristic analyzer. Generally referred to as small signal frequency. Opposite to this is the frequency of the machine, that is, the actual working frequency measured by the customer when the transducer is connected to the drive power supply through a cable. Because the customer's matching circuits are different, the same transducers with different drive power sources show different frequencies. Such frequencies cannot be used as an order basis.② Transducer capacitance: CT, unit: PFThat is, the free capacitance of the transducer, which can generally be measured with a capacitor bridge at a frequency of 400Hz-1000Hz, or an impedance characteristic analyzer can be used. To make it simpler, the measurement with a general portable capacitance meter can also meet the requirements.③ Working mode of transducerDue to different processing methods and requirements, the working mode of the transducer can be roughly divided into continuous work (lace machine, CD sleeve machine, zipper machine, metal welding, etc.) and pulse type work (such as plastic welding machine). Different working methods are different. The requirements for transducers are different. Generally speaking, continuous work has almost no pause time, but the working current is not very large, pulse work is intermittent, there is a pause, but the instantaneous current is large. On average, the power in both states is significant.④ Transducer type and high powerThe complete machine manufacturer may have different regulations for the nominal power of machines for different purposes. In other words, the same transducer may be used on different machines with a nominal power that is different. In order to avoid ambiguity, the customer should specify the structure type of the transducer, such as column type, inverted horn type, etc., and the diameter and number of piezoelectric ceramic wafers.⑤ Installation and fit dimensionsThe ultrasonic horn materials, surface treatment methods, and shapes. The ultrasonic welding transducer is connected with an ultrasonic horn, the ultrasonic welding horn is connected with an ultrasonic mold, and the diameter, thickness, notch, or number and position of the screw holes at the flange of the ultrasonic horn.

Why RPS-SONIC TRANSDUCER:

1. Every transducer with a only tracking number, you can check the parameter from our saler no matter how long it passed.

2. All transducer with one year warranty.

3. Specialized in ultrasound for more than ten years

4. Every transducer with 24hours old testing before shipment.

5. Good packing, no packing problem during the 10 years exporting business.

6. Every customer will get purchase records and there are certain rewards after accumulation

Service and shipment

- Warranty one year for transducer.

- You can contact us for technical inquiry any time.

- We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

- We supply customized products service for small quantity also.

- Shipment by FED-EX /DHL/UPS/TNT