20khz 2600w Ultrasonic Welding Generator RPS-DG4200

Description

| Frequency: | 20khz | Power: | 2600w |

|---|---|---|---|

| Color: | Black And White | ||

| High Light: | 20khz ultrasonic weld generator,2600w ultrasonic weld generator,RPS-DG4200 | ||

20khz 2600w Ultrasonic Welding Generator RPS-DG4200

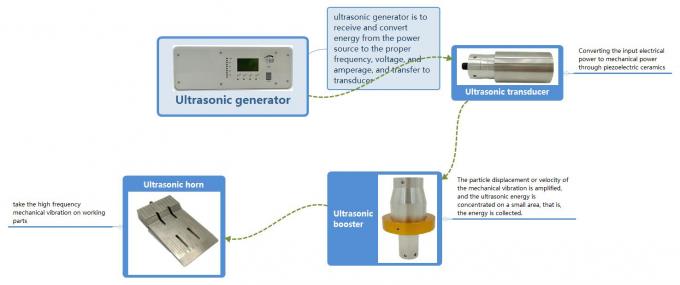

What's ultrasonic generator? Let the ultrasonic transducer and the ultrasonic generator drive power supply and the ultrasonic mold cooperate to form a complete ultrasonic equipment can be referred to as matching for short. Since the impact of matching on the performance of the whole machine is decisive, the importance of matching cannot be overstated no matter how much emphasis is placed on it. The most important factor for matching is the capacitance of the ultrasonic transducer, followed by the frequency of the transducer. It should be emphasized that the ultrasonic transducer itself is not an energy generator, it is just an energy converter. It converts electrical energy into sound energy (mechanical energy). Under the premise that the input (drive power) and output (amplifier, ultrasonic mold) are well matched, it can convert (output) a large amount of energy.

Ultrasonic transducer Input matching refers to the matching between the ultrasonic transducer and the ultrasonic power supply. If the output matching is good but the input matching is not good, the transducer is weak and the welding is not strong. If the output matching is not good but the input matching is good, the transducer will be overloaded, causing chip dislocation, cracking, breakage, screw breakage, aluminum cracking or burning the power tube of the electric box. For example, if a car slams on the accelerator in neutral, the engine must be easily damaged. The matching of ultrasonic transducer and driving power supply mainly has 4 aspects, namely impedance matching, frequency matching, power matching and capacitive reactance matching. Frequency matching is also very important. This is because the ultrasonic transducer can only work at its resonance frequency, so the drive power supply, horn, and welding die (tool head) should all work at this frequency. Generally speaking, we hope that this difference does not exceed ±0.1khz at most, and it is better if it can be smaller. We strongly recommend that the frequency of the matching welding die (welding head) is lower than the vibrator frequency about 0.1khz (small signal frequency). In other words, if the frequency measured by the small signal of the original vibrator is 14.85 khz, it is most ideal to measure the frequency after connecting the mold to 14.75 khz.

SECOND. Instructions of wire connection

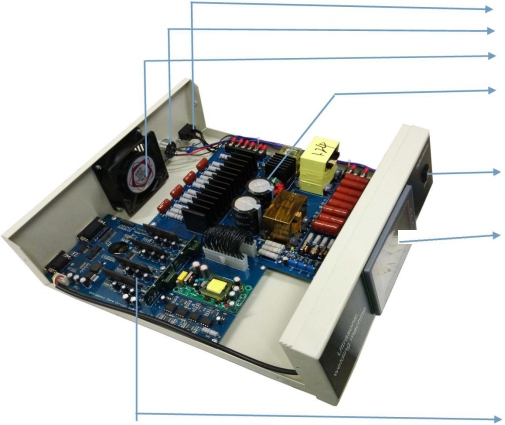

1. Wire connection of inner main board.

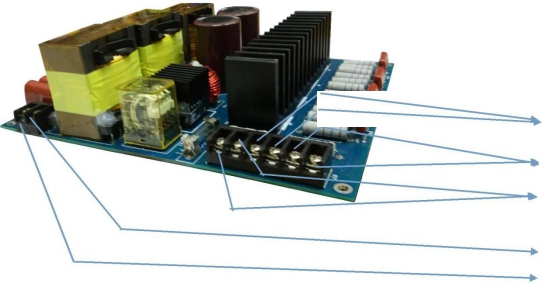

1. Wire connection of outerbox.