15khz customized ultrasonic horns for welding system with FEA analysis

Parameter:

| Item | parameter |

| Frequency | 15Khz |

| Welding area | 250*44mm |

| Material | Alumium alloy |

| Connect screw | 1/2-20 |

Introduction:

An ultrasonic horn (also known as acoustic horn, sonotrode, acoustic waveguide, ultrasonic probe) is a tapering metal bar commonly used for augmenting the oscillation displacement amplitude provided by an ultrasonic transducer operating at the low end of the ultrasonic frequency spectrum (commonly between 15 and 100 kHz). The device is necessary because the amplitudes provided by the transducers themselves are insufficient for most practical applications of power ultrasound.Another function of the ultrasonic horn is to efficiently transfer the acoustic energy from the ultrasonic transducer into the treated media,which may be solid (for example, in ultrasonic welding, ultrasonic cutting or ultrasonic soldering) or liquid (for example, in ultrasonic homogenization, sonochemistry, milling, emulsification, spraying or cell disruption).Ultrasonic processing of liquids relies of intense shear forces and extreme local conditions (temperatures up to 5000 K and pressures up to 1000 atm) generated by acoustic cavitation.

How does an Ultrasonic welder work? An Ultrasonic welder is a machine that uses kinetic energy from vibrations to heat and melt plastic together. The basic process comes down to a vibration frequency, measured in hertz, directing energy onto a section of the 2 parts you want to weld together.

The parts that are being welded are placed between the nest (commonly known as the anvil) and the sonotrode (commonly known as the horn). Both the horn and the nest is usually made from aluminium or titanium. The sonotrode is the connected to a transducer which emits the acoustic vibration. This vibration flows from the transducer, down the horn, and onto the part that is being welded. The frequency of the vibration can range from 15kHz all the way up to 70kHz.

The part design is usually critically. That part that contacts the horn, usually has a triangular lip that is protruding from the face that is being welded. The other part, that is contact with the nest, is held still and has a small groove that meets the protruding lip on the other part. The energy is concentrated into this lip, which is then heated and melted by the vibrations, and at a certain point this lips’ structure collapses and fills the groove with molten plastic.

Therefore, the ultrasonic horn is the part that directly works with the weldment, and the design of the ultrasonic hornaffects the welding effect of the weldment. At the same time, the ultrasonic horn also belongs to the consumables in the entire welding system. Generally, the transducer and the ultrasonic power supply can work for 5 to 10 years, but the ultrasonic horns is available for several months to several years according to different working conditions.

The mainissues for ultrasonic welding horn:

1) Uneven amplitude across the face of the horn was causing a weak weld at both ends of the seal area and

2) The horns were cracking and had to be replaced at an unacceptable rate .

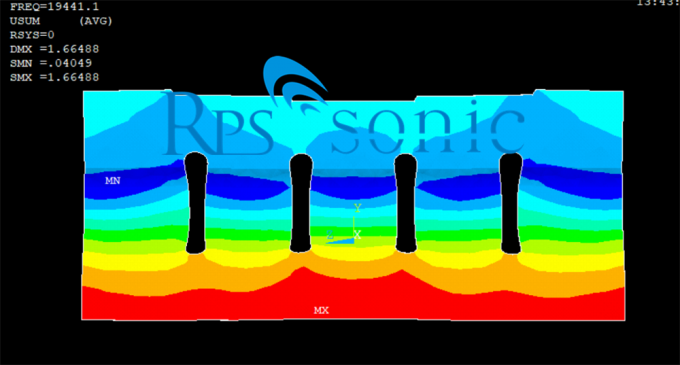

Both of these problems are caused by the uneven force on the cross section of the horn. The horn received too much ultrasonic power at a point, which caused cracking. At the same time, too much energy gathers at one point, resulting in insufficient capacity of other parts, low output, and uneven welding. How to effectively avoid this problem requires us to work hard when designing. Using the FEA analyzer, finite element analysis is performed when the horn is designed, and the force on the tool head section can be clearly known. The uniform and strong force on the horn section is the ideal state. as the picture shows:

Information required for quoting and designing an ultrasonic welding hornIf you are in need of a quote for an ultrasonic welding horn for a new application, here are a few key pieces of information that will be required by an ultrasonic horn manufacturer in order to provide you with an accurate quotation for the ultrasonic tooling:

- What's the dimension of the horn you need? if you have no dimension , tell us the welding area.

- Material - what's the horn material you prefer? Titanium alloy, alumium alloy, or steel?

- Quantity - How many parts do you anticipate producing (monthly, annually, life time, etc)?

- Frequency - What is the operating frequency of the ultrasonic welder that the ultrasonic horn will be used on (15 kHz, 20 kHz, 35 kHz, 40 kHz, etc)?

- Welder Information - What is the make and model of the welder that the ultrasonic horn will be used with (Herrmann, Branson, Dukane, etc)?

- Stud Size - What stud size is required to connect the ultrasonic horn to your booster (3/8-24, 1/2-20, M8x1.25, M10x1.5, M12x1.25, etc)?

- Depending upon the complexity of the application, more information may be required by the ultrasonic horn manufacturer but supplying the above information is a great place to start.

Why RPS-SONIC HORN:

1. Every horn will be designed by FEA system , so that to confirm theEnd face of the ultrasonic horn with uniform force

2. All ultrasonic horns with three months warranty.

3. Specialized in high power ultrasonic for more than ten years

4. Every ultrasonic hornwith 24hours old testing before shipment.

5. Good packing, no packing problem during the 10 years exporting business.

6. Every customer will get purchase records and there are certain rewards after accumulation

Service and shipment

- Warranty one year for transducer.

- You can contact us for technical inquiry any time.

- We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

- We supply customized products service for small quantity also.

- Shipment by FED-EX /DHL/UPS/TNT