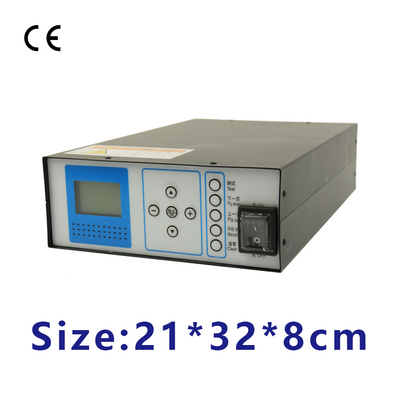

15khz 2600w Ultrasonic Welding Generator For Non Woven Slicer

Description| Frequency: | 15khz | Power: | 2600w |

|---|---|---|---|

| Color: | Light Gray | Usage: | Ultrasonic Welding,nonwoven Welding |

| High Light: | 2600w ultrasonic welding generator,15khz ultrasonic welding generator,ultrasonic non woven welding generator | ||

High Frequency 15khz 2600w Ultrasonic welding generator for mask slicer

What’s ultrasonic generator?

Ultrasonic generator welding system are ideally suited for surface treatment applications where space is at a premium. It is with compact design, digital frequency generation and control, absolutely constant power output and an integrated interval function, these generators set new standards in the power output range up to 42,000 Watts.

Ultrasonic generator welding system comes with various protective functions for the greatest operational reliability, such as the intelligent cooling system and protection against short-circuiting, no-load operation and overloading.

20KHZ1200W-2000W, 15KHZ2600W-4200W ultrasonic welding machine Non-woven welding, plastic welding, welding, PVC leather spot welding, ribbon cutting, heat sealing and other multi-functional welding equipment, outer ear tape The mask machine fuses the elastic bands on both sides of the mask body in an ultrasonic manner to complete the finished earband mask. Only one operator needs to place the mask body on the conveyor belt fixture, and the rest of the subsequent actions until the finished product is completed The machine operates automatically, and the output of this machine is higher than that of ordinary earband machines.

Ultrasonic welding generator features: 1. High stability: The ultrasonic welding generator adopts all-digital integrated circuits and imported high-performance anti-interference processors. It reduces the number of components, simplifies the hardware structure, and increases the voltage regulation function to improve the reliability and stability of the system.2. Frequency automatic tracking: digital frequency synthesis technology combined with digital phase-locked loop frequency tracking composite control technology can eliminate temperature, static load, processing area, tool wear and other factors drifting conventional analog regulator is difficult to overcome shortcomings, is conducive to parameter adjustment. It is convenient to modify the control scheme and implement various new control strategies through the modification of the program software.3. Strong output: It uses IGBT power module plus its exciting oscillating circuit structure, so that the output power is more than 1.5 times that of the traditional self-excited circuit.4. Amplitude stepless adjustment: the amplitude can be increased or decreased in the process of adjustment, and can also be fine-tuned, effectively preventing the size of the plastic parts can be perfectly welded, and effectively reducing the penetration, burns and so on. The setting range of defective product is 10%~100%.5. Intelligent protection and fault alarm prompt: This ultrasonic generator has mold current too high protection, frequency offset protection, total output too large protection. When the equipment fails, the generator will immediately stop working and prompt the corresponding fault cause until the technician removes the fault.Jiayuanda Technology - Professional ultrasonic welding generator manufacturers and suppliers in China, providing ultrasonic products for sale. Welcome to wholesale the best ultrasonic welding generator at competitive price from our factory.

| envirnmental factor | Applicable range |

| Operating/use temperature | +5°C to +50°C |

| Storage/transport temperature | -25°C to +70°C |

| Relative humidity | 30% to 95%, no condensation |

Generator part

The ultrasonic signal generator is composed of an ultrasonic power amplifier module that can convert 50/60 Hz industrial frequency alternating current into super audio frequency for the transducer to work, and a control module with "system protection monitoring" and "auto-tuning" functions. The control module can cut off the ultrasonic energy when the ultrasonic welding work fails, thus providing extremely high safety and reliability for the generator and the entire welding equipment.

1. Really automatic frequency tracking (AFC) adapts to various sizes of welding molds and different design molds. The frequency range of automatic tracking: ±400HZ (according to 15KHZ ultrasonic for example, the mold frequency can be used for automatic frequency tracking at 14.40-15.20KHZ). Frequency tracking accuracy: ±5HZ

2. Adopt CPU computer to monitor each program with fast speed, strong adaptability, built-in various

protection systems, "system protection monitoring" function will respond to the following situations:

u _ Excessive pressure leads to overload

u Ultrasonic generator current is too large

u _ Welding head, horn or transducer loose or other failure

u _ Generator circuit failure

u _ Faulty cable between generator and transducer

u Automatic compensation for unstable power supply frequency

3. The "automatic tuning" function enables the ultrasonic generator to automatically track and compensate

for changes in the welding head frequency. When the temperature is too high, the surface of the welding

head is worn or there is debris on the welding head, this frequency change will occur.

4. Built-in fully automatic constant amplitude system, which can automatically compensate for different air pressure changes and voltage fluctuations, and can adjust the ultrasonic amplitude from 50% to 100% steplessly to meet the requirements of different welding workpieces.

5.Using IGBT for power amplification, the response is fast, which is more than 100 times faster than

the traditional silicon power tube, so the protection function is better.

Voltage: 198-242VAC (50 / 60Hz), the output will be much weaker when AC110V input, need some adjustment, direct use is almost only used for cutting applications.

Volume: 384mm * 240mm * 110mm

Weight: 7KG

Color: light gray